Categorize

Email: 13925050263@139.com

text

Classifications:

Others

- 产品描述

-

- Commodity name: text

undefinedThe JEEPINE Bottle Cap Compression Molding System applys a precision-engineered rotary multi-stage compression mechanism coupled with an advanced electro-hydraulic control module, delivering unmatched dimensional accuracy and process stability under continuous high-throughput operation. Its multi-cavity design enables ultra-short cycle times and steady-state productivity, while the absence of hot-runner channels and minimized thermal gradients in both heating and cooling phases reduce overall energy consumption by nearly 45%. Spill-free operation ensures each polymer pellet is converted into finished closures, virtually eliminating raw-material scrap. Integrated safety interlocks, emergency-stop circuitry, and a U/L-certified frame allow fully enclosed, touch-free production to maintain hygienic integrity.

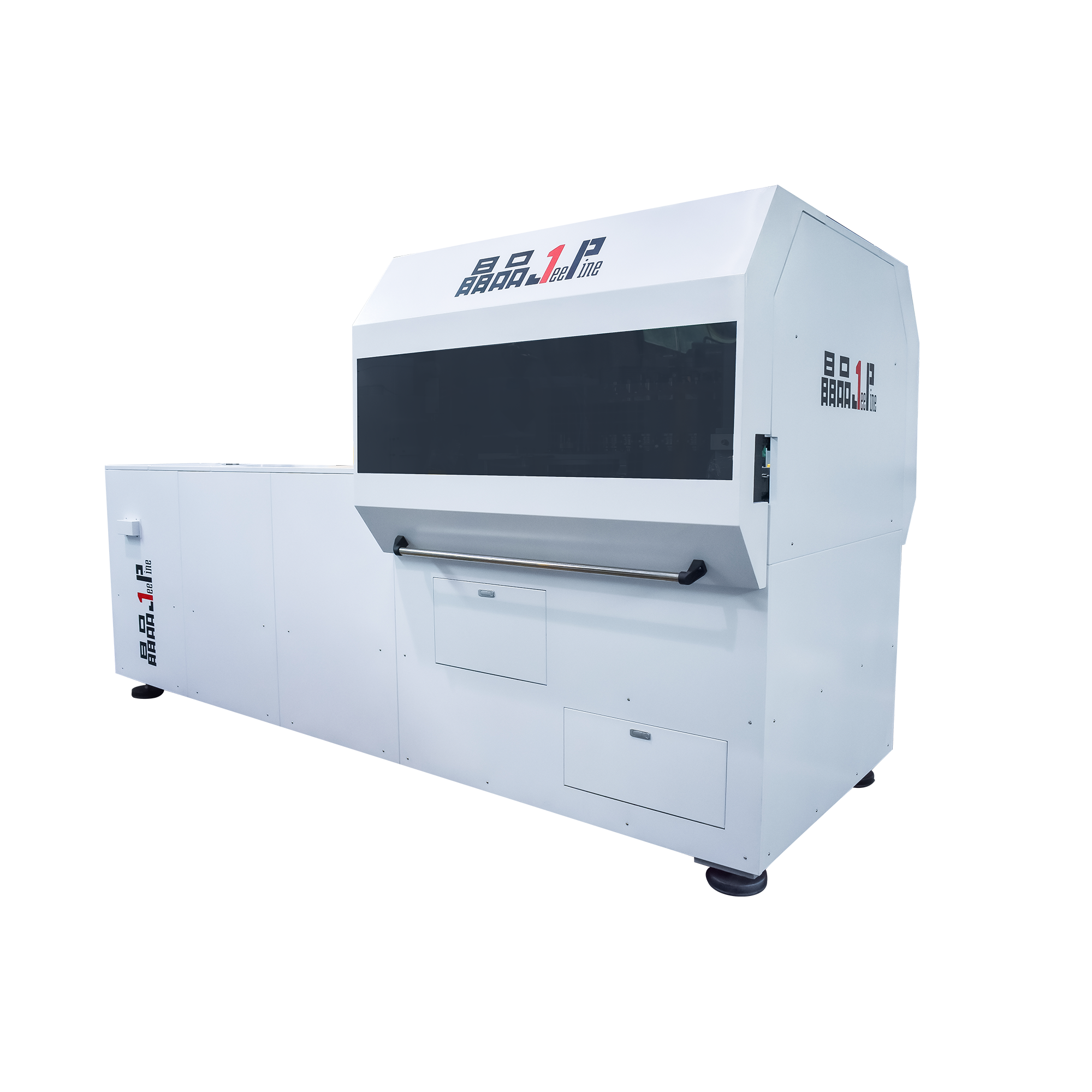

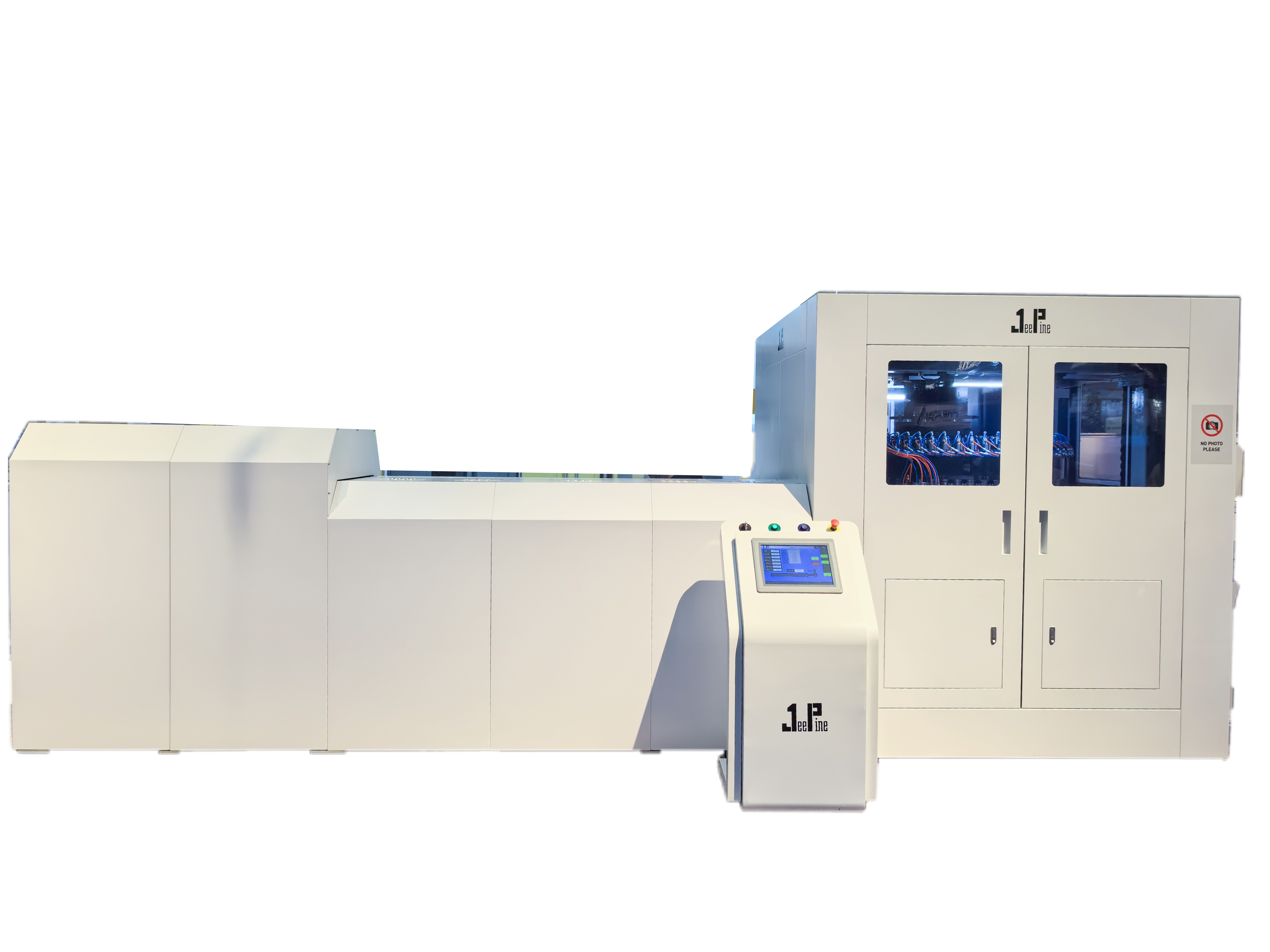

The JEEPINE Bottle Cap Compression Molding System applys a precision-engineered rotary multi-stage compression mechanism coupled with an advanced electro-hydraulic control module, delivering unmatched dimensional accuracy and process stability under continuous high-throughput operation. Its multi-cavity design enables ultra-short cycle times and steady-state productivity, while the absence of hot-runner channels and minimized thermal gradients in both heating and cooling phases reduce overall energy consumption by nearly 45%. Spill-free operation ensures each polymer pellet is converted into finished closures, virtually eliminating raw-material scrap. Integrated safety interlocks, emergency-stop circuitry, and a U/L-certified frame allow fully enclosed, touch-free production to maintain hygienic integrity.

Video relacionado

Related Products

Message to Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible