Categorize

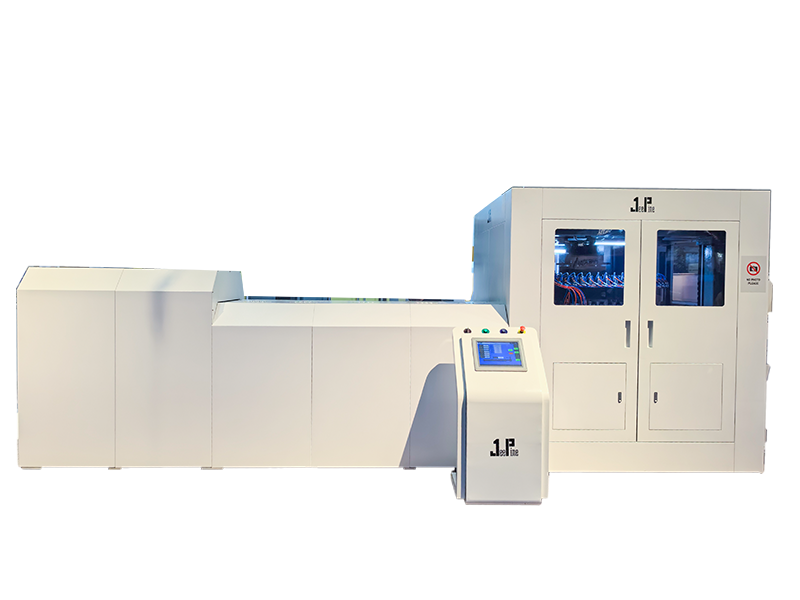

Plastic Bottle Cap Machine CCM-YSZG54

bottle cap

Plastic Bottle Cap Equipment

beverages bottle cap machine

Cap Making Machine

plastic bottle machine

Cap Compression Molding Machine

Bottle Cap Machine

Classifications:

Cap Compression System

- 产品描述

-

- Commodity name: Plastic Bottle Cap Machine CCM-YSZG54

- Commodity ID: 005

- 首页标题: CCM-YSZG54

Max Production Capacity: <strong>100,000Pcs/h</strong> Raw Materials: <strong>PE/PP</strong> Max Cap Size: <strong>35mm</strong>

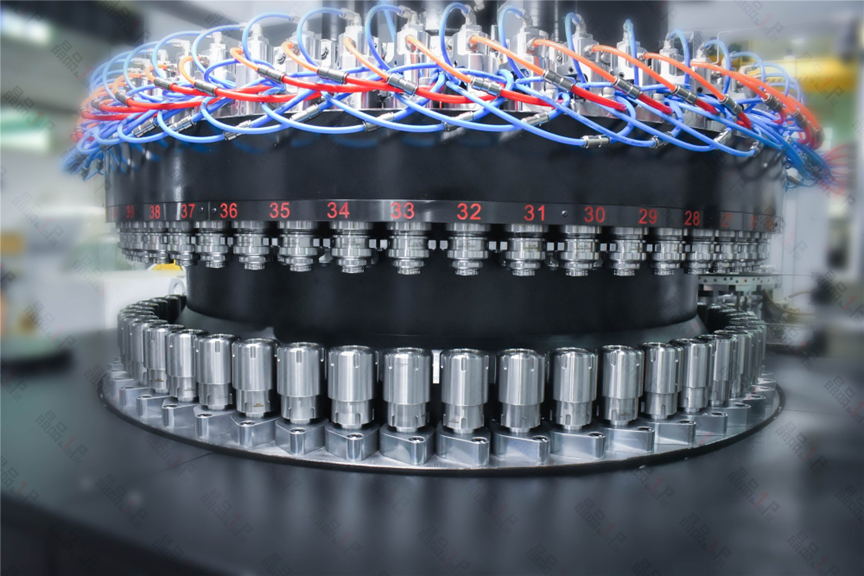

- Stable Integral turntable design, high-precision double-pump hydraulic system, PID algorithm control low-pressure molding and high-pressure molding, stable operation process.

- High Efficiency New type high-speed feeding system, continuous high-speed rotary pressing with multiple molds, vacuum adsorption cap, high production efficiency.

- Energy Saving Low temperature melting of raw material, low energy consumption for heating and cooling.

- Material Saving Intelligent temperature-controlled extrusion, quantitative cutting of raw material pellets, stable weight, full use of raw materials.

- Safety Intelligent logic control system, automatic monitoring, alarm, automatic diagnosis, automatic protection.

- Hygienic It can achieve the integration of cap making, bottle blowing, filling and capping, and has the functions of online production and online conveying, which is clean and hygienic.

Working Principle:

Full-automatic compression moulding cap making machine adopts upper and lower multi-mold high-speed rotary compression moulding process to manufacture plastic bottle caps such as water beverage cap, medicine cap, daily chemical cap, wine cap and so on. Granular plastic materials (such as PE, PP, etc.) are melted at high temperature and extruded through the extruder, the machine is quantitatively extruded from the nozzle, and then cut down by the cutting disc and evenly distributed to the every molds and finally pressed and moulded in the molds.

Application:

Jeepine cap compression molding machine breaks through the key technology of plastic machinery industry in the way of plastic moulding, solves the problems of high energy consumption, high material consumption and low production efficiency of the traditional plastic machinery, and meets the needs of the majority of domestic and foreign customers. Applicable to the production of mineral water bottle cap, dairy bottle cap, carbonated beverage bottle cap, high-temperature fruit juice bottle cap, cosmetic bottle cap, medical supplies bottle cap, edible oil bottle cap and other plastic bottle cap.

Advantages of the equipment:

The bottle cap made by this equipment process has no injection point, the cap is of good quality and beautiful appearance, and the product quality is at the leading level in the industry. The equipment is easy to operate, save electricity, water, raw materials, labour, and can save a lot of cooling water, no runner waste. High productivity, adopting continuous flow process, it is extremely convenient to change materials and molds, accurate and smooth transmission, scientific process, compact structure, small area of land, high return on investment.

Technical specifications CCM-YSZG54 Raw material PE/PP Max.outer dia. Φ35 mm Max.height 25 mm Max.weight 4 g Number of cavities 54 Max production capacity 100,000 Pcs/h Power consumption 122±5 Kw/h Machine dimensions 10×4.5×2.6 m

Video relacionado

Related Products

Bottle Cap Making Machine CCM-YSZG24

Beverages Cap machine CCM-YSZG48A

Plastic Bottle Cap Equipment CCM-YSZG48B

Message to Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible