Everything You Need to Know About Us

Guangzhou Jeepine Intelligent Compression Molding Machine Co.,Ltd

JEEPINE, founded in 2008 and headquartered in Guangzhou's Huangpu District, was listed on the NEEQ (New Third Board) in 2015 (Stock Code: 833127) as the first publicly listed enterprise in China's compression molding equipment industry. Specializing in high-efficiency, energy-saving Continuous Compression Molding (CCM) technology, the company maintains a professional R&D team led by senior experts and holds over 130 national patents. It has been recognized as the "Guangdong Provincial Engineering Technology Research Center for Compression Molding Equipment" and participated in drafting the national standard for "Plastic Cap Making Machines." JEEPINE's self-developed CCM cap-making machine has been included in China's National First-Set Catalog of major technical equipment, achieving domestic technological leadership and breaking foreign monopolies. The company serves renowned clients including Wahaha, Yinlu, Genki Forest, Mengniu, Wuliangye, and Danone, with products exported to multiple international markets across Asia, Africa, the Middle East, and the Americas, serving industries such as beverages, alcohol, pharmaceuticals, and daily chemicals.

Jeepine compression molding cap making machine has significant advantages in energy consumption and efficiency compared to the traditional injection molding cap making machine, and has won a number of national honors, including but not limited to:

01

Drafting Unit of the National/Industry Standard for 《Plastic Cover Cap Making Machine》

02

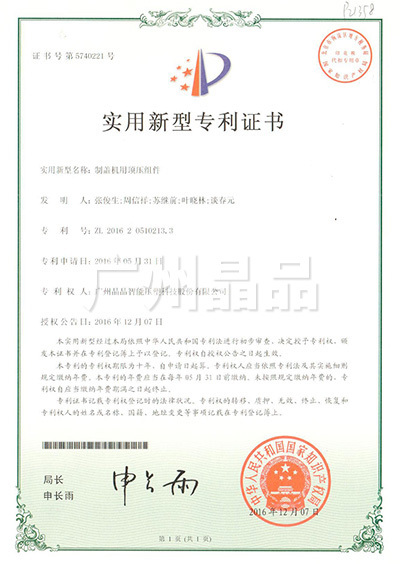

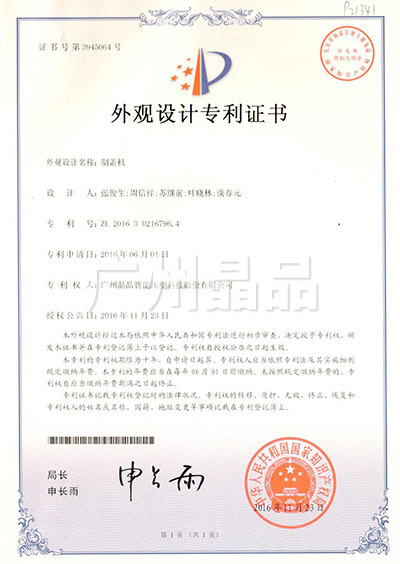

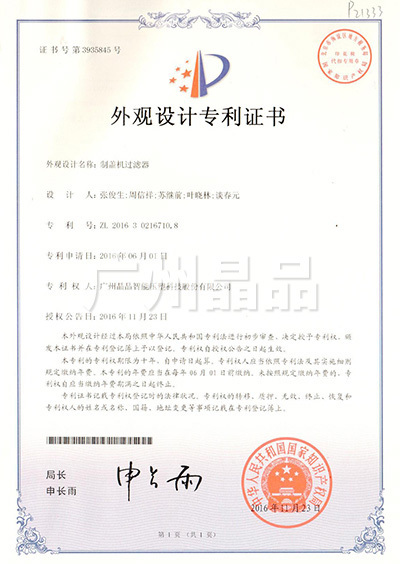

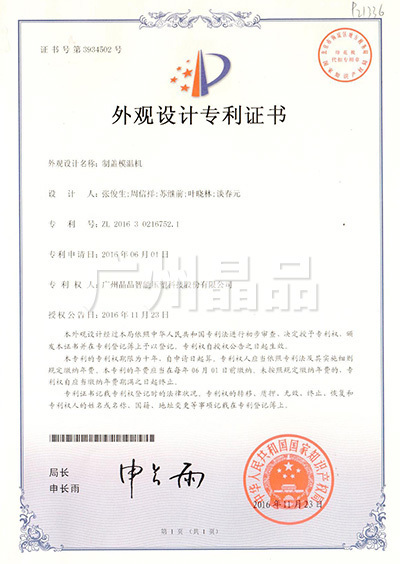

130+ technologies were patented

03

Undertook many national science and technology projects, such as the National Torch Program projects, National Innovation Fund projects.

04

Officially recognized as "Hihg Tech Enterprise",won award of "Guangdong Machinery Industry Science and Technology","Guangzhou Science and Technology progress"

05

Drafting Unit of the National/Industry Standard for 《Plastic Cover Cap Making Machine》

R&D Capability and Engineering Team

Jeepine has an independent R&D team, gathering professionals led by professors and senior engineers, and cooperating with South China University of Technology and its National Engineering Research Center for New Polymer Molding Equipment and Guangzhou Nonferrous Metals Research Institute for industry-university-research cooperation. The company spends 10%-20% of its annual revenue on R&D, covering mechanical design, mold design, electrical control system, CCM structure optimization, etc.

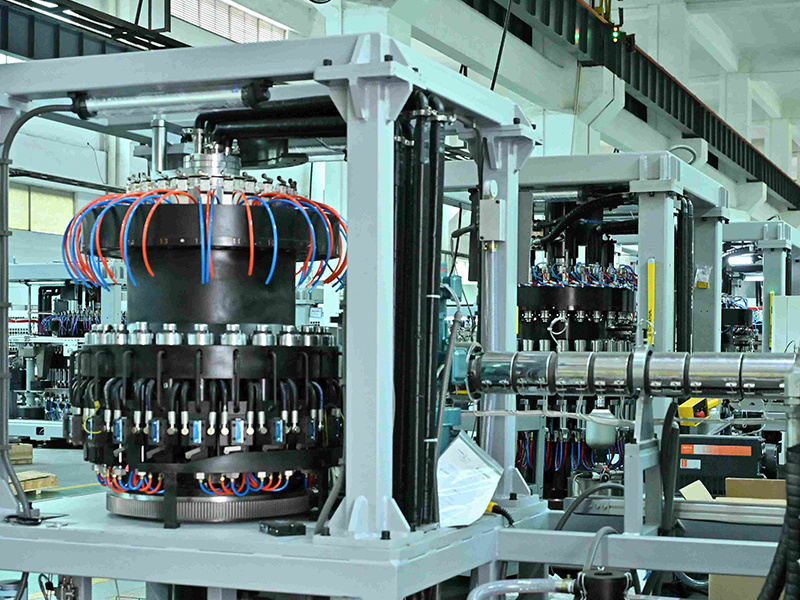

Production and Quality Management

Jeepine has the ability to process precision compression molds and large forgings, and owns a number of special processing equipments with international advanced level, such as HARTING high precision internal and external circular universal grinding machine, Japan Mazak CNC lathe, etc. The company implements whole-process quality control and has passed the TÜV-ISO9001:2015 quality management system certification, which ensures that the quality of products meets high standards.

Sales Network and Development Plan

Jeepine has been deeply cultivating in the domestic market and gradually expanding the international market, including Southeast Asia, America, Europe Middle East and Africa. In the future, the company will actively explore new economic growth points, accelerate product upgrading and improvement and the industrialization of new products, further optimize the allocation of resources, strengthen the training of talents, enhance cost control, and is committed to becoming a global leading compression molding equipment manufacturer.

Development History

2024

2023

2022

2021

Certificates

Certificates

Certificates

Certificates

Certificates