Categorize

Introduction to Plastic Bottle Cap / Water Cap Manufacturing Machine

Compression Molding Machine

Classifications:

Others

- 产品描述

-

- Commodity name: Introduction to Plastic Bottle Cap / Water Cap Manufacturing Machine

- Commodity ID: 020

Introduction to Plastic Bottle Cap / Water Cap Manufacturing Machine

What Are Plastic Bottle Cap & Mineral Water Cap Manufacturing Machines?

Plastic bottle cap manufacturing machines are specialized automated equipment designed for producing packaging caps for the food, beverage, chemical, and pharmaceutical industries. Their core function is to transform raw materials like polyolefins (PE/PP) into standardized bottle caps through injection molding or compression molding processes. These machines typically integrate the following key modules:

Raw Material Handling System

Utilizes high-precision screw extruders to heat polyethylene (PE) or polypropylene (PP) pellets to a molten state, achieving uniform plasticization through screw rotation. For instance, PP is widely used for mineral water caps due to its heat resistance, while PE is preferred for strong thread-removal structures owing to its elasticity.Mold Forming Unit

Equipped with multi-cavity cold runner molds capable of producing dozens of caps simultaneously. The mold design must precisely control thread profiles (e.g., M22×1.5 standard neck finishes) and sealing ring dimensions (typically 0.5-1mm thick) to ensure proper cap-to-bottle sealing.Automated Demolding & Inspection System

Mechanical arms are employed for rapid cap-mold separation, synchronized with visual inspection (for flaws like burrs or short shots) and leak testing. Advanced models integrate positive pressure leak testers simulating 1.2MPa environments to verify pressure resistance.Post-Processing Module

Includes tamper-evident band cutting, laser coding (production date/batch number), and counting/packaging systems. For example, mineral water caps require evenly distributed pull-tabs on tamper-evident bands, ensuring breakaway force is controlled within 15-25N.

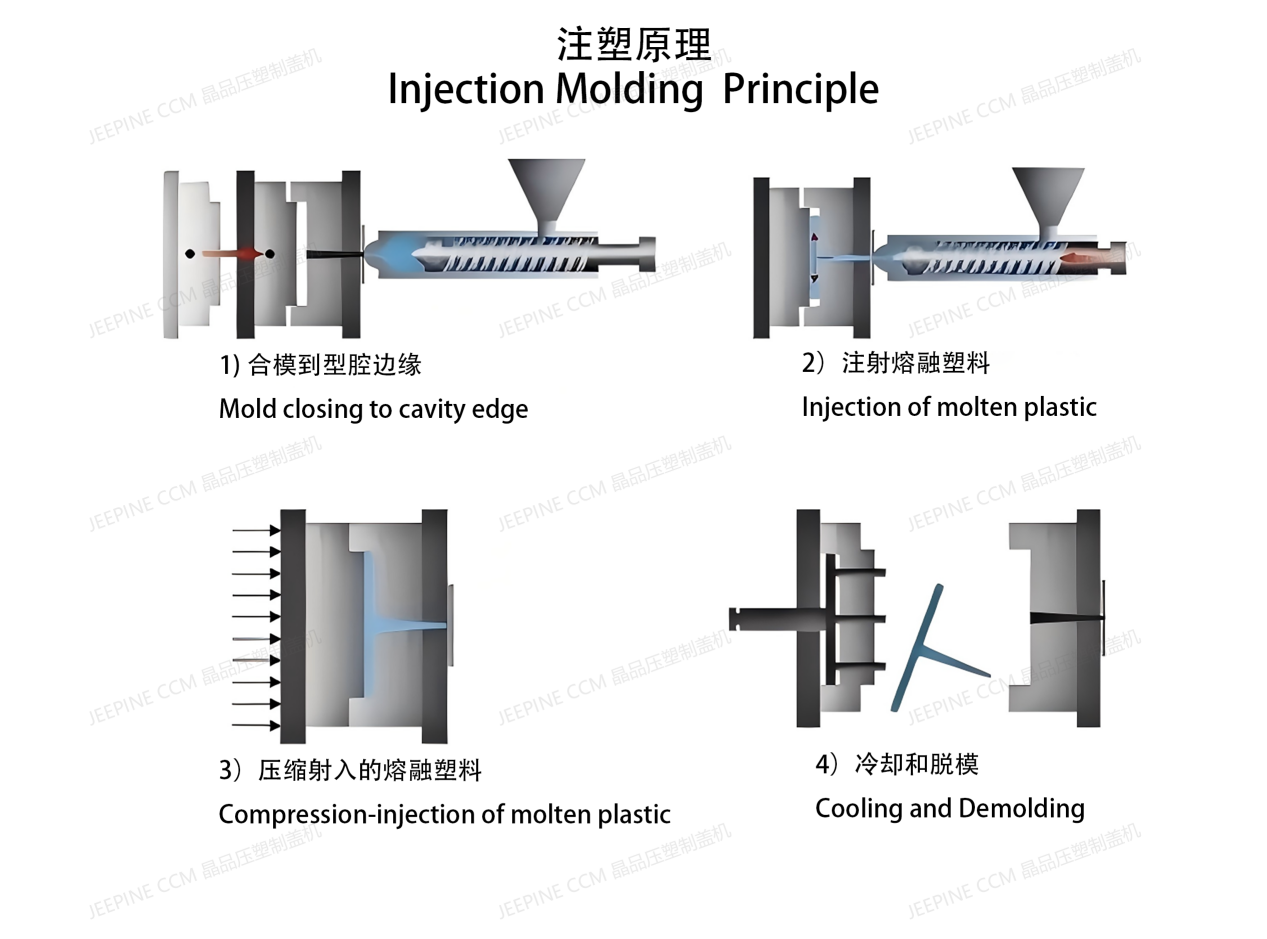

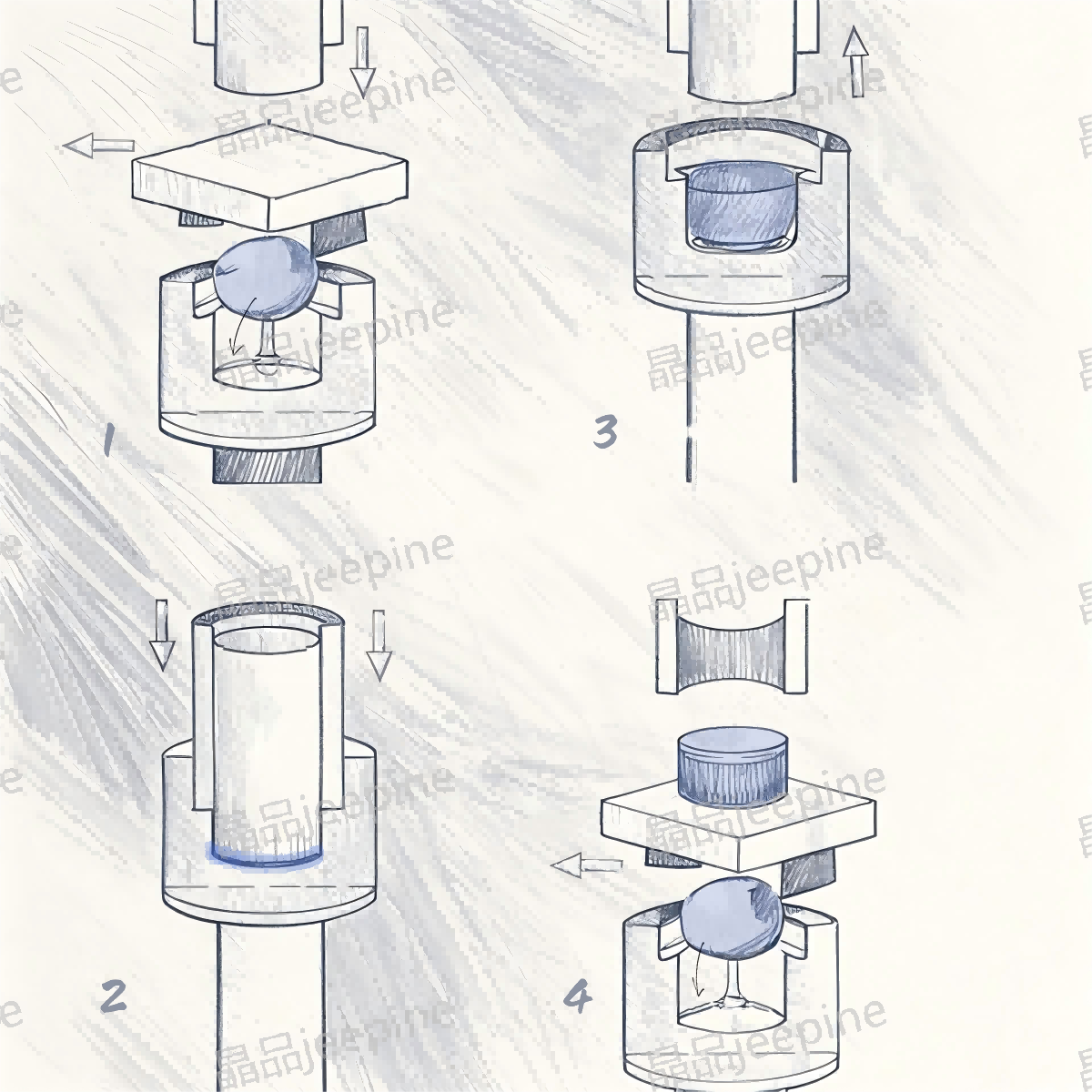

How to Choose Manufacturing Processes for Plastic & Mineral Water Bottle Caps?

In the early stages of plastic bottle cap manufacturing, injection molding technology was the dominant process widely used for large-scale production. However, with increasing demands for higher production efficiency, energy conservation, superior product quality, and environmental performance, traditional injection molding has shown limitations such as high energy consumption, long cycle times, and inconsistent product quality.

To address these challenges, the rotary cap compression molding technology emerged as an innovative solution. Based on continuous extrusion and in-mold compression, this process operates at lower temperatures and shorter cooling times, offering superior dimensional accuracy, lower shrinkage, and significantly improved efficiency — making it an increasingly important method in the cap manufacturing industry.

Wide Range of Applications

Rotary cap compression molding has been widely adopted across various industries for the production of liquid packaging closures. Its main application areas include but are not limited to:

Drinking water caps: High productivity, consistent quality, excellent sealing performance

Carbonated soft drink caps (CSD Caps): High internal pressure resistance and precise sealing

Dairy and juice caps (Hot Filling Caps): Withstand high-temperature filling, deformation-resistant

Pharmaceutical and daily chemical caps: Clean production compatibility with anti-leak and tamper-evident features

Aseptic caps (CAF Caps): Ideal for cold aseptic filling lines, meeting stringent hygiene and sealing requirements

As consumers pay more attention to packaging quality and product safety, compression molding has become the preferred solution in the beverage, food, pharmaceutical, and cosmetic sectors.

About Jeepine: Smart Compression, Future Manufacturing

Guangzhou Jeepine Intelligent Compression Molding Machine Co., Ltd., founded in 2008, has focused on the R&D and manufacturing of rotary cap compression molding machines for over a decade. Jeepine is committed to providing efficient, energy-saving, and intelligent cap production solutions to customers around the world.

As a pioneer in China’s cap compression molding industry, Jeepine holds independent intellectual property rights and possesses full capabilities in machine design, mold development, process optimization, and system integration. Jeepine’s equipment has been widely adopted by top packaging companies, including Wahaha, Yinlu, Genki Forest, Mengniu, Taiji Group, Huiyuan, Runtian, Chameleon, and Tan Hiep Phat Group, gaining strong market recognition.

Leading Technology, Reliable Quality

Jeepine’s independently developed compression molding machines outperform traditional injection molding machines with the same number of cavities in multiple aspects:

50% energy saving: Thanks to low-temperature extrusion processing

50% higher productivity: Shorter cycles and more efficient forming

High precision and consistency: Cap weight tolerance within ±0.05g, ensuring excellent sealing and torque performance

No injection gate residue: Better appearance, suitable for direct printing and visual inspection

Jeepine’s main products include 24-cavity, 48-cavity, and 54-cavity cap compression molding machines, compatible with PP/HDPE materials. These machines are built for high-capacity, 24/7 production environments, meeting the needs of cap factories producing tens of millions of units annually.

Innovation-Driven Growth, Strong R&D Capability

Jeepine has always regarded technological innovation as the core driver of its development. Since its inception, the company has applied for over 130 national patents, and has undertaken several major scientific projects at the national, provincial, and municipal levels, such as the National Torch Plan and National Innovation Fund.

Jeepine is recognized as a National High-Tech Enterprise and participated in drafting the national industry standard for cap compression molding machines. The company also serves as the supporting institution of the Guangdong Provincial Engineering Technology Research Center for Compression Molding Equipment, further proving its strong R&D and industry leadership.

Global Recognition and Bright Prospects

In 2015, Jeepine was successfully listed on the National Equities Exchange and Quotations (NEEQ) with stock code 833127, becoming the 【first publicly listed company in China’s cap compression molding sector】, and marking a significant milestone in the industry.

Jeepine’s products have been exported to Southeast Asia, the Middle East, Africa, Europe, and North America, continuously breaking foreign technology monopolies and promoting the global presence of Chinese intelligent manufacturing.

Looking ahead, Jeepine will continue to focus on the cap compression molding field, drive smart and green manufacturing, and strive to become a world-leading provider of bottle cap compression molding solutions, working hand in hand with global partners to lead the industry into a new era of high-quality, sustainable development.

Video relacionado

Related Products

undefined

Message to Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible