Categorize

3025 bottle caps for mineral water bottles

3025 bottle cap

beverages bottle cap machine

bottle cap

plastic closure

3025 plastic cap

3025 bottle closure

water cap

Classifications:

Products

Cap Types Introduction

- 产品描述

-

- Commodity name: 3025 bottle caps for mineral water bottles

Basic introduction to the 3025 bottle cap: What is the 3025 bottle cap? Applications of the 3025 bottle cap; Technical requirements for the 3025 bottle cap.

I. Basic Introduction to 3025 Bottle Caps

- What is a 3025 bottle cap?

The 3025 cap is suitable for bottled non-carbonated beverages using the 30/25 standard bottleneck (according to the classification of GB/T17876-2010, it does not belong to carbonated caps and is not suitable for carbonated beverages containing carbon dioxide).

2.What size bottle mouth is the 3025 bottle cap compatible with?

The bottleneck of the 3025 cap application products must meet the size requirements of GB/T17876-2010 "30/25 Standard Bottleneck" (support ring diameter 34.00 ± 0.15mm, thread diameter 30.30 ± 0.13mm, etc.), otherwise they will not fit the 3025 bottle caps.

The bottleneck of the 3025 cap application products must meet the size requirements of GB/T17876-2010 "30/25 Standard Bottleneck" (support ring diameter 34.00 ± 0.15mm, thread diameter 30.30 ± 0.13mm, etc.), otherwise they will not fit the 3025 bottle caps.- What products are 3025 bottle caps typically used for?

Common application products for 3025 bottle cap include:

- Bottled drinking water: Mineral water, purified water, natural water, mineralized water, etc. (e.g., some 500mL, 1L ambient temperature drinking water).

- Juice-based beverages: Freshly squeezed juice, concentrated/reconstituted juice, composite juice (e.g., orange juice, apple juice, fruit and vegetable juice mixed drinks).

- Tea beverage: Green tea, black tea, oolong tea, floral tea, herbal tea (e.g., sugar-free tea, flavored tea drinks).

- Plant-based protein beverage: Soy milk, walnut drink, almond drink, coconut milk, peanut milk, etc.

- Dairy beverages: Yogurt drinks, lactobacillus drinks, ambient temperature milkshakes, flavored milk beverages (non-carbonated type).

- Functional beverages (non-carbonated): S6.ports drinks, vitamin supplement drinks, electrolyte drinks (formulations without carbon dioxide).

- Other non-carbonated beverages: Honey water, goji berry water, herbal wellness drinks, bottled herbal tea (non-carbonated formula), etc.

II. Performance Requirements for Bottle Caps 3025 (According to China GB/T17876-2010)

1. Printing Pattern Adhesion Performance

The printing pattern on the 3025 cap should not show significant peeling and should not affect the integrity of the pattern.

2. Sealing performance

Non-carbonated caps (the 3025 cap fits the 30/25 standard bottleneck and belongs to caps for non-carbonated beverages) should meet: no air leakage at 200kPa, and no cap detachment at 350kPa.

3. Low-temperature resistance performance

After the low-temperature resistance test, the 3025 cap should not crack or deform, and should not leak when inverted.

4. Drop Performance

After undergoing a drop test, the 3025 bottle caps remain securely attached and do not leak.

5. Physical Properties of the Tamper-Evident Band

The physical properties of the tamper-evident band on the 3025 cap should comply with:

Project

Specification

Capping Performance

The tamper-evident band should not break after capping.

Tamper-Evident Performance

After opening, the connecting bridges of the tamper-evident band should show obvious damage.

Opening Torque

Between 0.6~2.2N·m

Breakaway Torque

Not greater than 2.2N·m

Video relacionado

Related Products

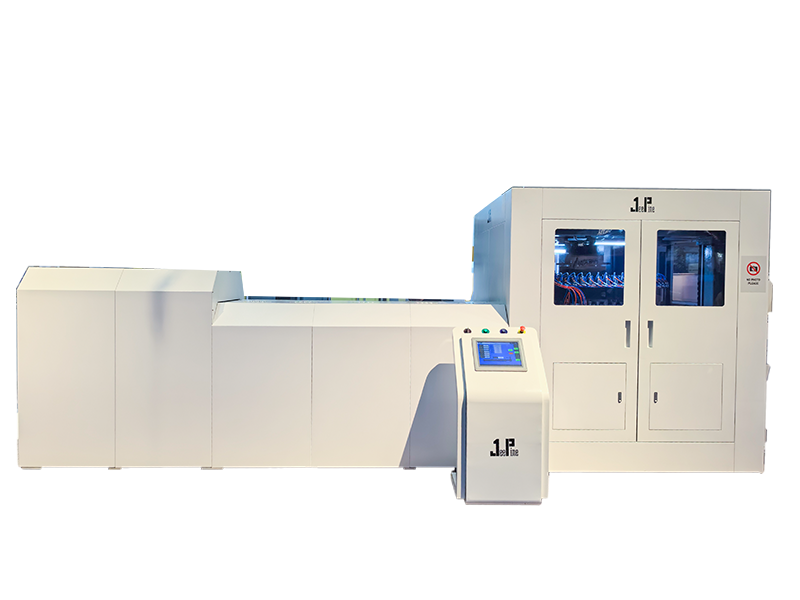

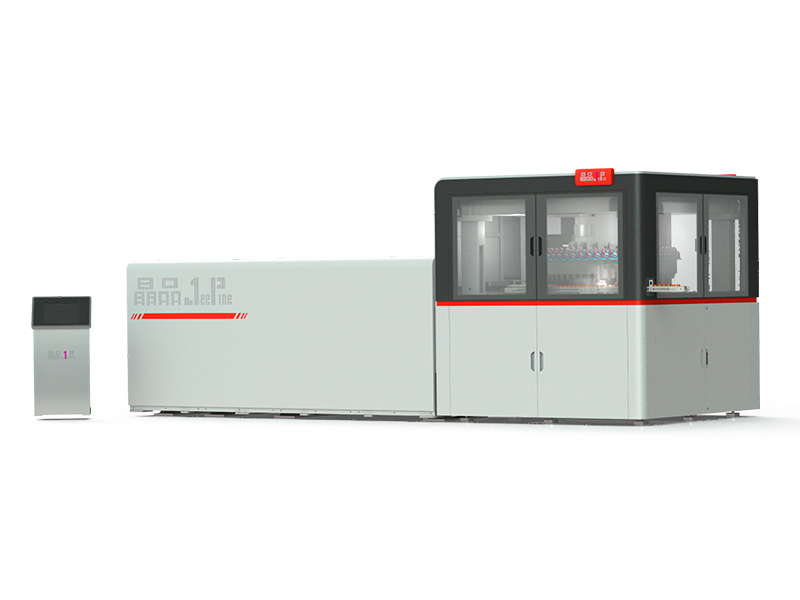

Bottle Cap Making Machine CCM-YSZG24

Plastic Bottle Cap Machine CCM-YSZG54

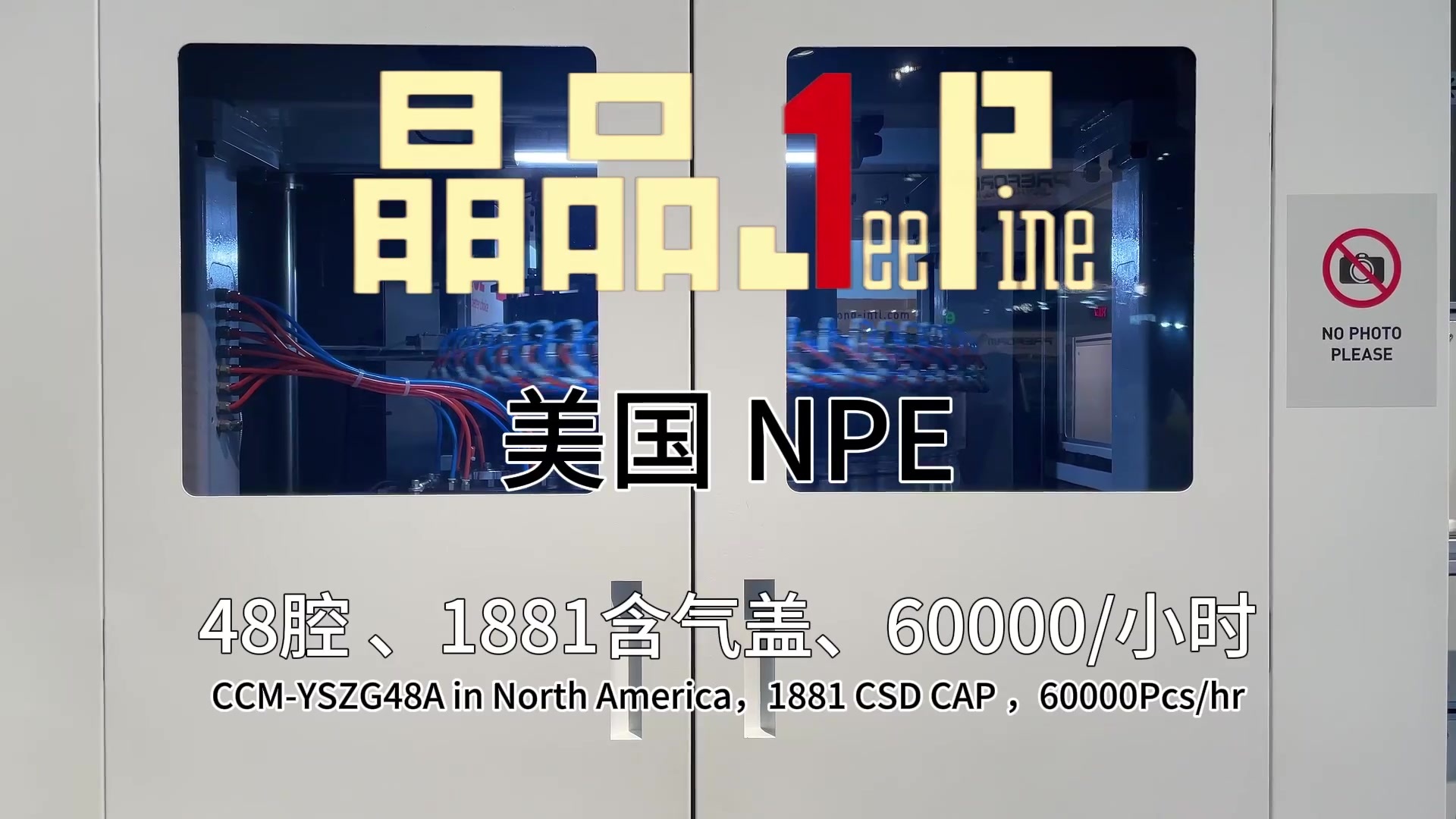

Beverages Cap machine CCM-YSZG48A

Message to Us

* Note: Please be sure to fill in the information accurately and keep the communication unblocked, we will get in touch with you as soon as possible