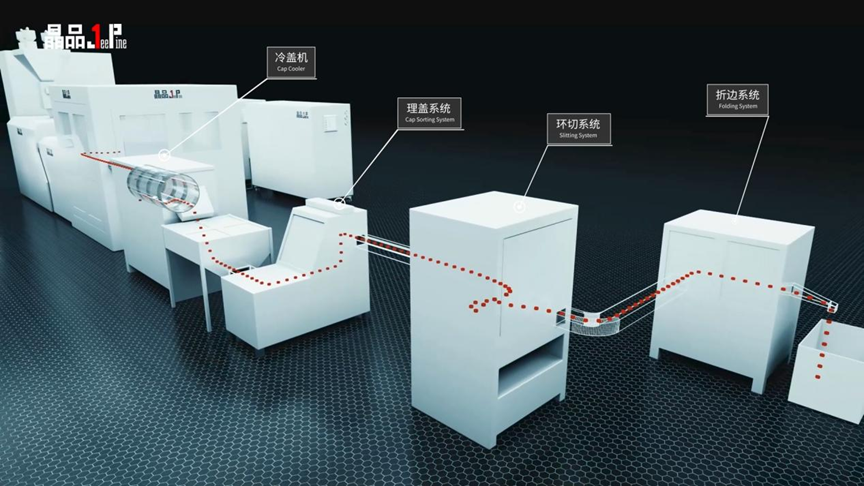

Jeepine Cap Compression Molding System Overview

Aquí está el texto del marcador de posición

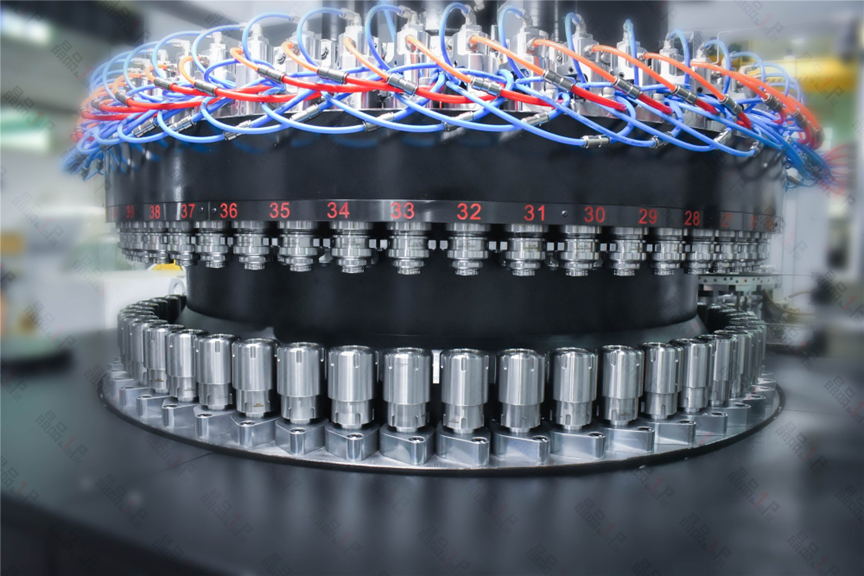

The Jeepine cap compression molding system integrates a high-precision rotary multi-stage compression mechanism with an advanced electro-hydraulic control unit, ensuring outstanding dimensional accuracy and process stability while maintaining continuous high-output operation. Equipped with multi-cavity molds, the system supports ultra-short molding cycles and sustained high-efficiency productivity. Compared to traditional injection molding, it eliminates the hot runner structure and significantly reduces the temperature difference between heating and cooling, effectively lowering overall energy consumption.

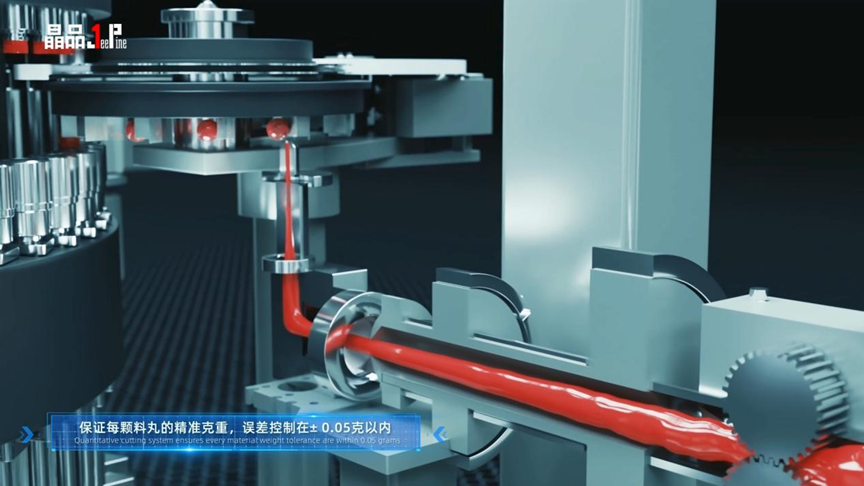

The system operates under a zero-flash production mechanism, ensuring that resin pellet is fully converted into a finished product, minimizing material waste and greatly reducing raw material scrap rates. Meanwhile, the system features an integrated safety interlock system and emergency stop circuit, delivering a fully enclosed, contact-free production environment to ensure hygiene and operator safety.

Compared to conventional injection molding, Jeepine’s compression technology enhances thermal efficiency by lowering mold temperatures, producing caps with higher density and lower shrinkage, resulting in greater dimensional stability. The extruder is directly connected to the mold, simplifying the material path and eliminating the need to clean hot runners during color changes—significantly reducing setup time. A rapid cooling design inside the mold cavity shortens the cycle time to approximately 2 seconds, dramatically improving overall line throughput.

In addition, the system adopts a modular independent mold structure, allowing fast mold replacement using standard hand tools without lifting equipment, enabling flexible and efficient operations. With near-zero material waste and high production cycles, the system significantly reduces the unit production cost per cap.

Jeepine has also innovatively developed high-efficiency cooling molds made of high-strength, wear- and corrosion-resistant alloy materials, enhanced with high-hardness surface coatings. The molds feature a surrounding liquid cooling loop, enabling uniform temperature control and precise dimensional management. Compared to traditional molds, this design boosts productivity by approximately 45%, greatly accelerating return on investment.

This compression molding system is specially designed for the beverage, food, and pharmaceutical packaging industries, ideal for the stable mass production of high-precision polymer caps such as water caps, CSD caps, hot-fill caps, and aseptic cold-fill caps. It fully meets international requirements for performance, regulatory compliance, and aesthetic quality.

The equipment is shipped using export-grade reinforced packaging and loaded into standard shipping containers, ensuring safe and damage-free delivery over long-distance transport.

Keywords: Compression Molding Machine | Bottle Cap Production Line | Energy-Saving Closure Equipment | High-Output Cap Manufacturing System | Precision Polymer Closure Solutions