Main ProductS

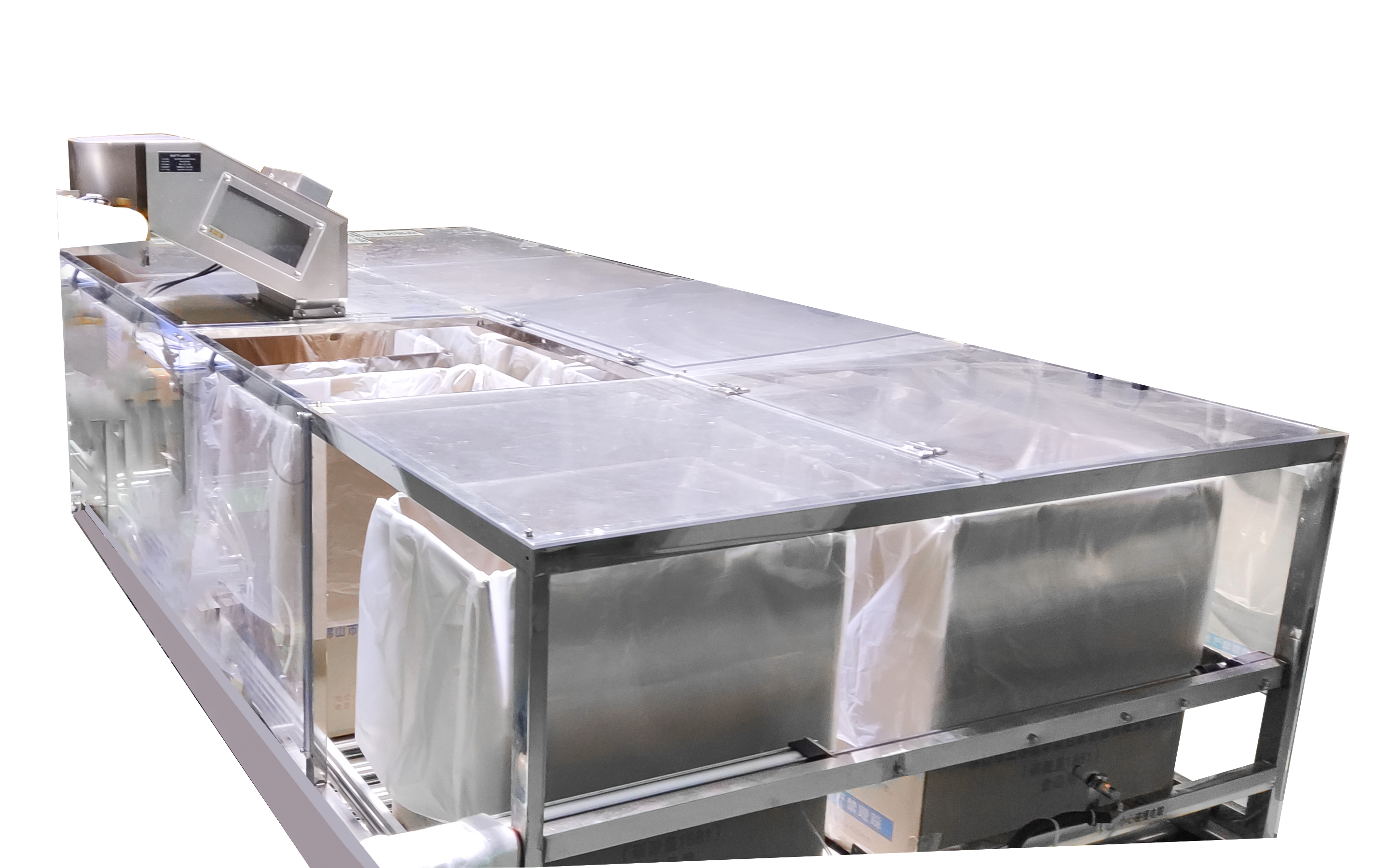

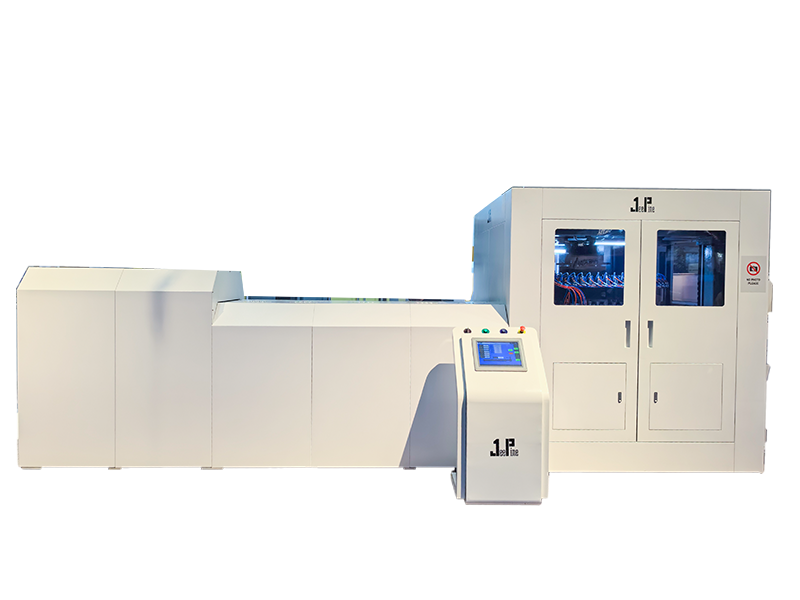

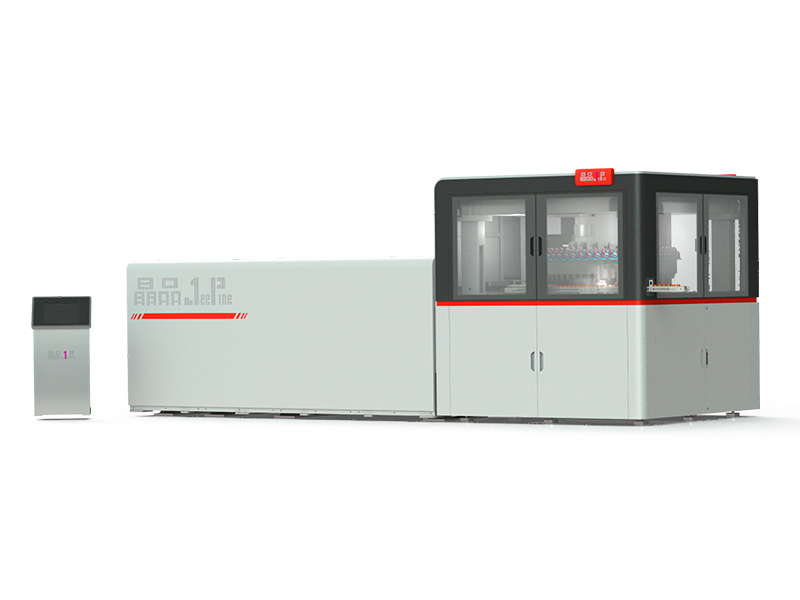

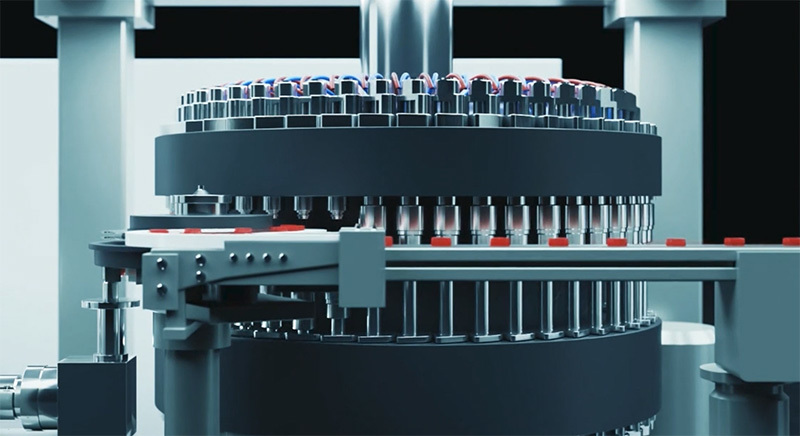

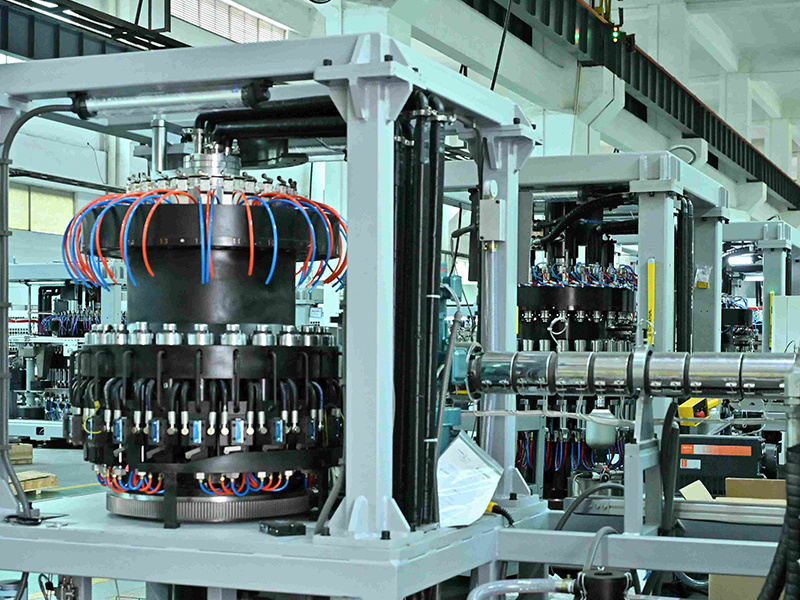

Jeepine Cap Compression Machine

Global Customer References

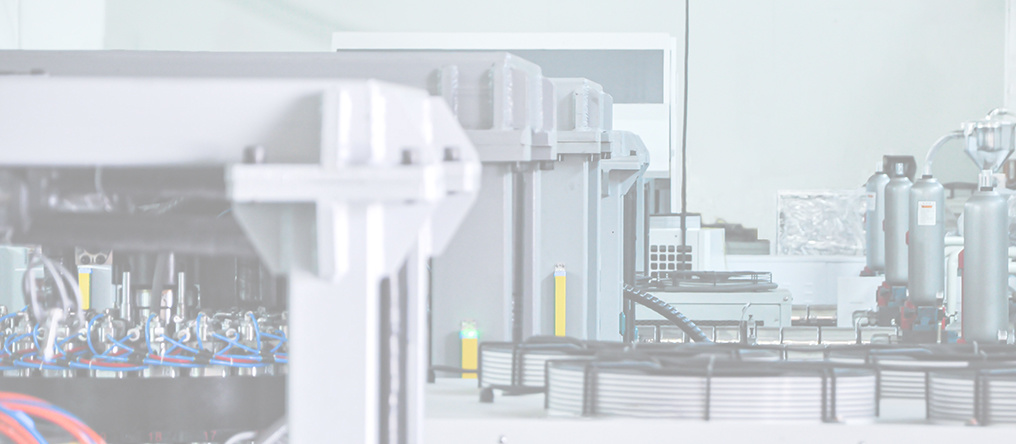

Jeepine cap compression molding technology and machines serve customers in over 35 countries, our key accounts includes Wahaha, Chi Forest, Jianlibao , Danone, AJE, etc. Up till now , over 600 Jeepine CCM are running on the market to creat value for customers in the industry of drinking water, beverages, alcoholic drinks, personal care products, medical , edible oil, etc. We stive for continuous innovation and technological progress of CCM to bring more reliable , high quality , less power consumption, high price performance ratio machine to customers , Jeepine provides you a better choice of your plastic closure production line.

JEEPINE CAP COMPRESSION MACHINE ADVANTAGES

JEEPINE & INDUSTRY NEWS

Nov 06,2025

Jul 24,2025

Jul 24,2025