JEEPINE CAP COMPRESSION MACHINE ADVANTAGES

Why Choose JEEPINE Compression Molding Capping Machines?

Stability

Jeepine’s intelligent compression molding machines deliver stability in two key areas: machine operation and product quality.

Machine stability is achieved through a one-piece turntable structure, machined in a single process on a large gantry machining center to ensure concentricity and enhance overall reliability. The molds undergo multi-stage heat treatments—including low-/high-temperature tempering and cryogenic processing—to improve corrosion resistance, toughness, and wear resistance. Critical components are coated with Diamond-Like Carbon (DLC) for enhanced durability, corrosion resistance and thermal stability.

Based on robust running, Jeepine'CCM integrates proprietary technologies to ensure consistent product quality. A self-developed extrusion screw enables uniform mixing and temperature distribution of materials. Combined with multi-zone intelligent temperature control, this ensures efficient heating and plasticization. Finally, high-speed precision cutting technology maintains pellet weight within ±0.05g, enabling consistent speed and pressure during material supply.

High Speed

The maximum capacity of the Jeepine Intelligent Cap Compression Molding Machine can reach 100,000 pcs/h. The equipment adopts low-temperature melting and continuous compression molding technology. This addresses the limitation of the intermittent processing method inherent in traditional injection molding equipments, which require waitin0g a certain period of time between high-temperature injection molding, cooling and forming, mold opening, and demolding, thereby significantly enhancing production efficiency.

Concurrently, a more efficient multi-channel conformal cooling mold structure greatly reduces the molding cycle of the products, thus further improving production efficiency. Each cavity of the mold has an independent cooling system, which solves the inefficiency problems associated with the indirect mold cooling structures found in traditional cap-making machinery.

Energy Saving

Jeepine's intelligent temperature control extrusion system employs a new polymer low-temperature melting technology, processing raw materials at lower temperatures. Simultaneously, the multi-zone intelligent temperature control of the system further reduces the energy consumption required for heating the raw materials. On the other hand, the lower temperature of the melted plastic particles also means lower energy consumption is required for mold cooling.

Material Saving

Benefiting from its excellent stability, the Jeepine Intelligent Cap Compression Molding Machine ensures a high product qualification rate while achieving continuous high-speed production. Continuous production reduces material waste during equipment shutdowns and subsequent preheating restarts. This will enhance the utilization rate of raw materials.

Furthermore, with Jeepine's R&D capabilities we can achieve lightweight cap production while ensuring the product's performance is not inferior to, or even better than, previous cap designs. This further saves raw materials and reduce the cost of cap production.

Safety

The Jeepine Intelligent Cap Compression Molding Machine adopts an intelligent logic control system and a remote control system. This system includes two main functions: predictive fault alerts and online equipment fault diagnosis. By analyzing the operational status of various components through historical database data, the system provides timely warnings for abnormal conditions, enabling proactive maintenance before equipment fault occurs. When the machine fault, after the customer confirms authorization and connects CCM to the network, the after-sales engineer can connect the PLC controller and the VPN network and use dedicated software to assist the customer in analyzing and resolving the fault. Additionally, this technology allows for remote upgrades and updates of PLC software, ensuring the long-term stable running of the equipment.

Beyond this, the Jeepine Intelligent Cap Compression Molding Machine adopts a highly automated detection system. The entire set of equipment can be started with a single button. After pressing the start button, the equipment automatically performs self-checks on the cooling system, the hydraulic system, the feeding system, the safety system, etc. If any abnormality is detected, it will automatically alarm.

Hygiene

Jeepine's complete compression molding cap production line can be seamlessly integrated into blow-fill-seal (or blow-mold-fill-cap) production lines. There is no need for traditional carton packaging, centralized warehousing, road transportation, manual unpacking and other steps. enabling integrated production, reducing manual intervention and secondary contamination.

JeePine provides diversified cap solutions covering a wide range of industries such as food, beverage and pharmaceuticals:

Carbonated cap

Such as 2622 CSD CAP for carbonated beverages.

Bottled Water Cap

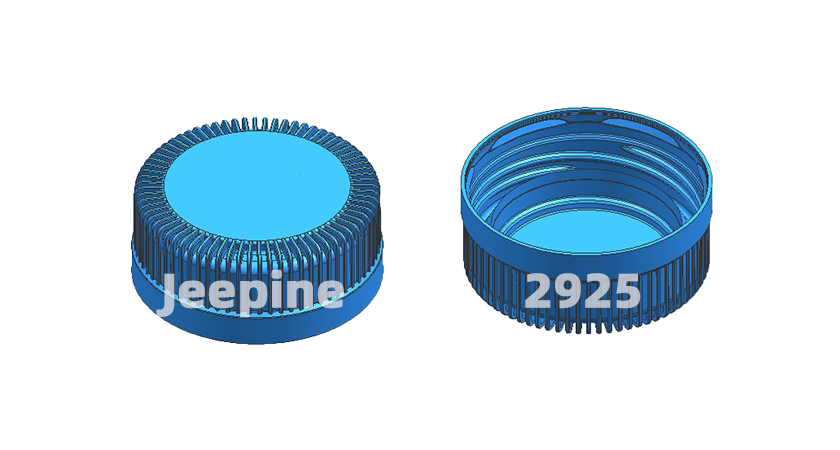

Such as 3025/2625/2925/2622/2722

For purified and mineral water.

Pharmaceutical caps

e.g. 28mm caps for pharmaceutical products.

Special application caps

e.g., toothpaste, liquor, motor oil caps

For daily chemical, liquor & chemical industries

Each solution specifies in detail the cap raw material (HDPE), bottle mouth size (e.g., 26mm, 28mm, etc.), sealing structure (inner stopper + outer stopper), weight (e.g., ranging from 1.1g to 6.9g), and application areas (e.g., carbonated beverages, water, fruit juices, dairy products, etc.), which allows for lightweighting, diversification, customization, and the development of new cap styles to ensure that we meet the various needs of our customers.

Cap Types Introduction

3025 WATER CAP

2622 CSD CAP

1881 CSD CAP

2925 WATER CAP