Water bottle cap solutions

Jeepine Bottled Water Closure Production Solutions

1. Overview of Plastic Closures for Bottled Water

Plastic closures are essential components for bottled water packaging. Directly contacting drinking water, they provide critical barriers against gas permeation, moisture ingress, and contamination while preventing content leakage.

2. Classification of Water Closures

Manufactured primarily from HDPE or PP, key types include:

| Type | Material | Neck Finish | Seal Structure | Thread | Weight | Application | |

|---|---|---|---|---|---|---|---|

| 26mm Closure | HDPE | 26mm | Olive Inner+Outer Plug | 3-Start | 1.2g | Purified/Mineral Water | |

| 27mm Closure | HDPE | 27mm | Olive Inner+Outer Plug | 3-Start | 1.4g | Purified/Mineral Water | |

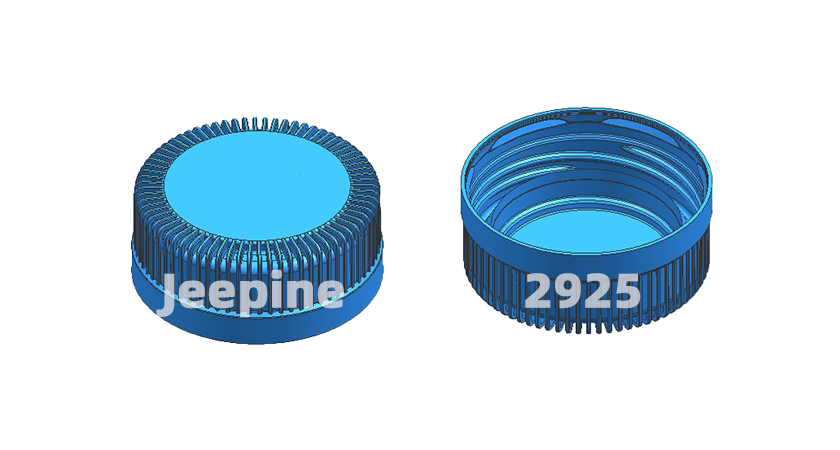

| 2925 Closure | HDPE | 29mm | Olive Inner+Outer Plug | 3-Start | 1.3g | Purified/Mineral/Distilled Water | |

| 3025 Closure | HDPE | 30mm | Olive Inner+Outer Plug | 3-Start | 1.85g | Purified/Mineral Water | |

| PCO 1880 | HDPE/PP | 28mm | Inner+Outer Plug | - | 2.8g | Water, Juice, Dairy, Energy Drinks | |

| PCO 1881 | HDPE/PP | 28mm | Inner+Outer Plug | - | 2.3g | Bottled Water & Beverages | |

| 38mm Smart Cap | HDPE | 38mm | Inner+Outer Plug | Double-Start | 3.4g | 4.5L Water Jugs | |

| 48mm Smart Cap | HDPE | 45mm | Inner+Outer Plug | Single-Start | 6.8g | 4L/5L/8L/12L Water Jugs | |

3. Working Principle

Jeepine's fully automatic compression molding machine utilizes rotary multi-cavity molding:

Material Processing: PE/PP granules melted and extruded quantitatively;

Forming: Cutter wheel segments extrudate → preforms distributed to molds → high-pressure compression molding;

Output: Production of closures for water, pharma, cosmetics, and liquor.

4. Key Advantages

Stability: Integrated turret + dual-pump hydraulics, PID-controlled molding;

Efficiency: High-speed feeding + continuous rotary compression + vacuum ejection;

Energy Saving: Low-temp melting reduces heating/cooling consumption;

Material Saving: ±0.01g weight tolerance via precision dosing;

Safety: AI logic control with real-time monitoring/alerts/diagnostics;

Hygiene: Integrated "Make-Closure / Blow-Fill-Seal" lines, minimizing contamination.

5. Complete Line Solution

Compact Footprint

Easy Maintenance & Safe Operation

Fully Automatic

Broad Process Window Flexibility

6. Six Core Systems

Compression System: Automatic closure molding

Cooling & Orienting: Rapid cooling + automatic unscrambling

Slitting System: High-precision hot-slitting

Printing System: Fully automatic, superior print quality

Inspection System: High-speed camera defect ejection

Packaging System: IR counting + automated boxing, zero manual contact

JeePine provides diversified cap solutions covering a wide range of industries such as food, beverage and pharmaceuticals:

Carbonated cap

Such as 2622 CSD CAP for carbonated beverages.

Static water cap

Such as 2622 WATER/CAF CAP, for purified water or mineral water.

Pharmaceutical caps

e.g. 28mm caps for pharmaceutical products.

Special application caps

e.g. white wine inner cap, toothpaste cap, etc.

Each solution specifies in detail the cap raw material (HDPE), bottle mouth size (e.g., 26mm, 28mm, etc.), sealing structure (inner stopper + outer stopper), weight (e.g., ranging from 1.1g to 6.9g), and application areas (e.g., carbonated beverages, water, fruit juices, dairy products, etc.), which allows for lightweighting, diversification, customization, and the development of new cap styles to ensure that we meet the various needs of our customers.

Recommended Solution

Cap Types Introduction

3025 WATER CAP

2622 CSD CAP

1881 CSD CAP

2925 WATER CAP