Dairy bottle cap solutions

JEEPINE Dairy Bottle Cap Production Solution

Q: What is a dairy bottle cap?

A:

1. Introduction to Dairy Bottle Caps

Plastic caps for dairy bottles are essential accessories that interface directly with the product. They provide critical functions such as gas barrier performance, moisture resistance, and contamination prevention. On one hand, they prevent the contents from leaking out; on the other, they block foreign particles from entering, ensuring product quality and safety

2. Types of Dairy Bottle Caps

Type | Material | Diameter | Seal Structure | Weight | Typical Applications |

PCO 1881 | HDPE or PP | 28 mm | Inner + Outer Seal | ≈2.3 g | Mineral water, juice, dairy, functional drinks, tea beverages |

PCO 1880 | HDPE or PP | 28 mm | Inner + Outer Seal | ≈2.8 g | Mineral water, juice, dairy, functional drinks, tea beverages |

38 mm Cap | HDPE | 38 mm | Inner + Outer Seal | ≈3.5 g | Water, juice, dairy, tea beverages |

46 mm Cap | HDPE | 48 mm | Inner + Outer Seal, Triple Thread | ≈4.6 g | Water, juice, dairy, functional drinks, tea beverages |

3. Cap Manufacturing Process

The JEEPINE dairy cap machine is a fully automatic compression-molding system featuring high-speed rotary molds. It produces plastic caps for water, pharmaceutical, daily-chemical, and alcoholic beverage bottles. The process is as follows:

Heat and melt PE/PP pellets, then extrude a metered flow via the screw

A cutting disk slices the molten material and distributes it evenly to each cavity

High-speed rotary compression in the mold forms the cap, which is cooled and ejected

4. Key Advantages

High Stability: Integrated turntable + dual-pump hydraulics + PID control enable low-pressure clamping and high-pressure forming for stable operation

High Productivity: Advanced feed system + multi-cavity rotary compression + vacuum-assisted ejection increase throughput

Energy Saving: Low-temperature polymer melting reduces heating and cooling energy consumption

Material Efficiency: Intelligent temperature control + precise cutting ensure consistent weight and minimize waste

Intelligent Safety: Real-time monitoring, alarms, self-diagnosis, and protection functions

Hygiene & Cleanliness: Integrated cap forming, blowing, filling, and capping with inline transfer reduces manual contact

5. Your Ultimate Cap Solution

Compact Footprint

Easy Maintenance & Safe Operation

High Level of Automation

Wide Process Window

6. Six Core Systems

Cap Compression System: Fully automatic compression molding, outstanding performance

Cooling, Buffering & Unscrambling: Rapid cooling and automatic unscrambling for stability and efficiency

Hot Slitting System: High-precision hot cutting for clean edges

Printing System: Fully automatic printing with crisp, durable graphics

Optical Inspection System: High-speed imaging and intelligent ejection of defects

Packaging System: Automatic cap loading with infrared counting minimizes manual contact and ensures food safety

JeePine provides diversified cap solutions covering a wide range of industries such as food, beverage and pharmaceuticals:

Carbonated cap

Such as 2622 CSD CAP for carbonated beverages.

Bottled Water Cap

Such as 3025/2625/2925/2622/2722

For purified and mineral water.

Pharmaceutical caps

e.g. 28mm caps for pharmaceutical products.

Special application caps

e.g., toothpaste, liquor, motor oil caps

For daily chemical, liquor & chemical industries

Each solution specifies in detail the cap raw material (HDPE), bottle mouth size (e.g., 26mm, 28mm, etc.), sealing structure (inner stopper + outer stopper), weight (e.g., ranging from 1.1g to 6.9g), and application areas (e.g., carbonated beverages, water, fruit juices, dairy products, etc.), which allows for lightweighting, diversification, customization, and the development of new cap styles to ensure that we meet the various needs of our customers.

Cap Types Introduction

3025 WATER CAP

2622 CSD CAP

1881 CSD CAP

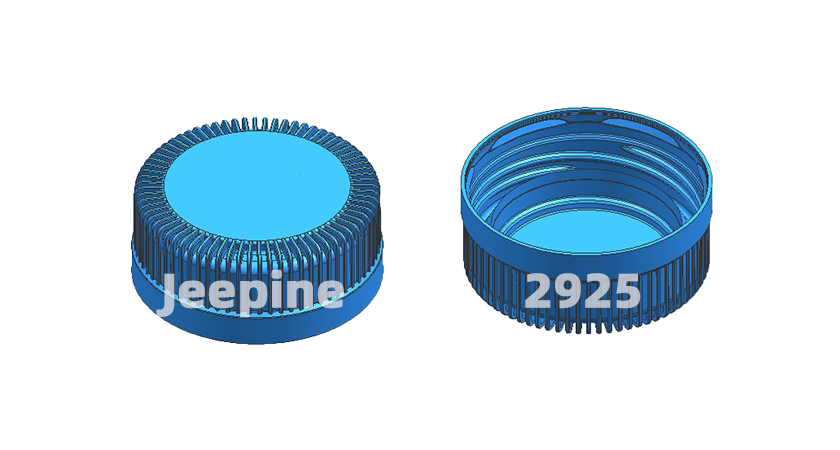

2925 WATER CAP