20

2026

-

01

Comprehensive Technical Analysis of 2925 Bottle Caps

1. Structural Design Features (Complying with Mandatory National Standard Performance Requirements)

Sealing system: Olive-shaped inner plug + outer plug double sealing + three-section thread design, meeting the sealing requirement of "non-carbonated caps: no air leakage at 200kPa and no cap detachment at 350kPa" in 5.4 of the national standard, preventing water leakage and deterioration of contents.

tamper-evident band design: Disposable tamper-evident band (with connecting bridge), which breaks after opening, complying with the "tamper-evident performance" in 5.4 of the national standard: no pre-damage after capping, and obvious damage marks after re-capping.

Lightweight structure: Compared with the 3025 cap, the height is reduced and the weight is reduced by 0.2-0.3g, realizing the optimization of material and logistics costs under the premise of meeting the impact resistance and drop performance of the national standard.

Process adaptability: Compatible with compression molding (popular, high density, stable size) and injection molding processes, meeting the requirement of "formed by injection molding, hot pressing or other processes" in 1 of the national standard.

- Core Physical and Mechanical Properties (Mandatory National Standard Requirements + Market Verified Indicators)

Performance Item | National Standard Requirements (Non-carbonated Caps) | Market Application Significance | Test Method (National Standard Clause) |

Sealing Performance | No leakage at 200kPa; no cap detachment at 350kPa | Prevent beverage leakage and pollution; ensure shelf life | Underwater pressure holding test for 1min |

Opening Torque | 0.4-2.2N・m (H≤12mm, specification <38mm) | Balance opening convenience and sealing reliability (market conventional measured value: 0.9-1.13N・m, corresponding to 8-10 in-lbs) | Test with a torque meter with accuracy >0.1N・m after standing at room temperature for 24h |

Break Torque | ≤2.2N·m | Ensure the tamper-evident band breaks smoothly when opening; avoid difficulty in opening | Test with a torque meter and observe the state of the connecting bridge |

Low Temperature Resistance | No bursting, no deformation, no liquid leakage after freezing at -4℃±1℃ for 24h | Adapt to cold chain transportation and low-temperature storage scenarios | Place sideways for freezing and then invert for observation |

Drop Performance | 1. Vertical drop at 4℃/1.4m (<1L); 2. Lateral drop at room temperature/1m (≥1L); no cap detachment or liquid leakage in both cases | Cope with impact risks during logistics and transportation | Test by capacity classification |

Impact Resistance | After standing at 4℃ for 24h, impact 4 parts with a steel ball (φ41mm/286g) from a height of 762mm; no cracking or detachment | Avoid damage caused by accidental impact during handling | Group impact on top center/edge, 45° angle, and side wall |

Grease Bleeding Performance | No grease-like substances precipitated on the liquid surface | Ensure the hygiene and safety of beverages; avoid affecting taste | Place sideways at 42℃ for 48h and observe regularly |

Safe Opening Performance | No cap detachment or popping when opening | Prevent splashing or cap flying out to hurt people at the moment of opening | Simulate the actual opening process for testing |

3. Material and Hygiene Performance (Mandatory Compliance Requirements of National Standards)

Core material: Food-grade high-density polyethylene (HDPE, polyolefin), meeting the requirement of "taking polyolefin as the main raw material" in 1 of the national standard;

Hygiene standards:

Raw material hygiene: Complies with GB9687 (polyethylene molded products) and GB9685 (additive use)

Finished product inspection: Tested according to the method of GB/T5009.60, with harmful substances such as heavy metals and volatile substances up to standard

Environmental protection trend: Some manufacturers have developed bio-based HDPE versions to meet the requirements of sustainable development

III. Application Scenarios and Market Adaptability

1. Core Application Scope

Adapted products: Room temperature/cold-filled bottled water (purified water, mineral water, distilled water), fruit juice drinks, tea drinks, sports drinks and other non-carbonated drinks, and some condiment packaging

Adapted bottle types: Lightweight PET bottles (especially suitable for lightweight bottle types treated with nitrogen), disposable non-recyclable bottles; only applicable to cold-filling production lines (not suitable for hot-filling)

Market penetration rate: Has become a standard configuration for mainstream brands such as Master Kong, Wahaha, and Ganten, with a continuously increasing market share, gradually replacing traditional 3025 caps

2. Key Comparison with 3025 Caps (Including National Standard Compliance Differences)

Comparison Item | 2925 Cap | 3025 Cap | National Standard Level Differences |

bottleneck Adaptation | 29mm outer diameter, 25mm thread | 30mm outer diameter, 25mm thread | Both need to comply with national standard dimensional tolerances and adaptation principles |

Weight | 1.25-1.3g | 1.5-1.8g | Neither has mandatory weight requirements; 2925 is better suited for lightweight trends |

Height | Shorter (≤12mm) | Taller | 2925 corresponds to the opening torque of 0.4-2.2N・m in the national standard; 3025 adapts to the corresponding range according to height |

Sealing Performance | Meets national standard requirements for non-carbonated caps (no air leakage at 200kPa) | Same as above; partially used in scenarios with higher sealing requirements | No essential difference; depends on structural design |

Cost | Lower (material + logistics) | Higher | 2925 is more in line with cost optimization needs |

Market Trend | Rapid growth, becoming mainstream | Gradually being replaced, retaining specific scenarios | Both comply with national standards; 2925 is more suitable for modern packaging trends |

IV. Production, Inspection and Compliance Requirements

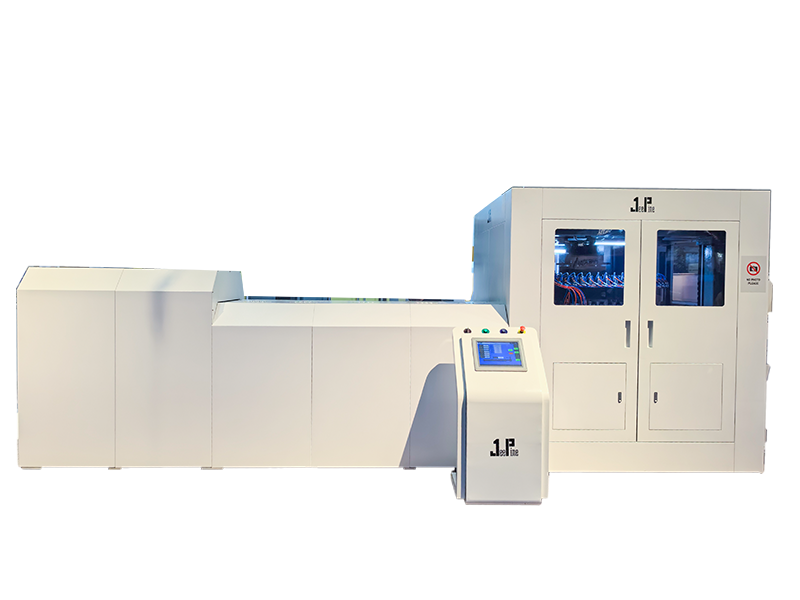

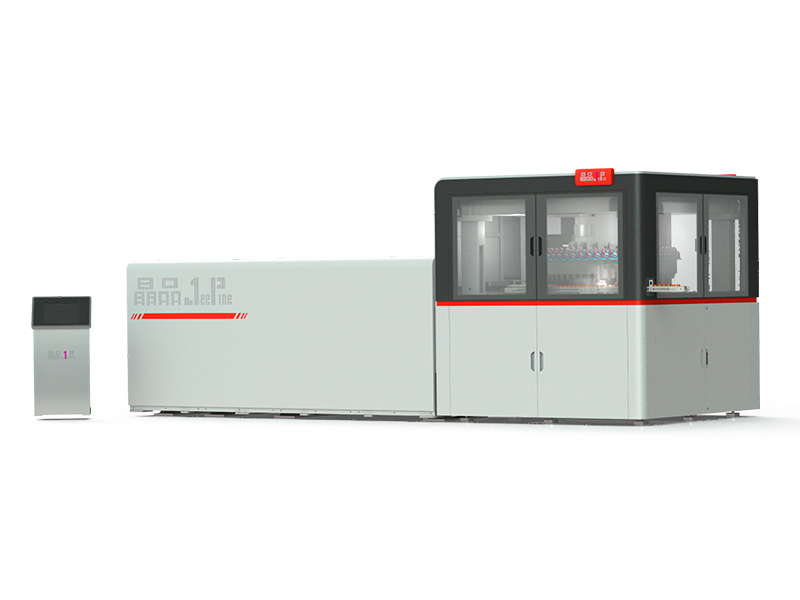

1. Production Process and Equipment

Mainstream processes: Compression molding (recommended, with high finished product density, stable size and beautiful appearance) and injection molding, both meeting the "molding process" requirement in 1 of the national standard

Production control: Need to ensure the hygiene and compliance of raw materials (complying with GB9685 additive use standards) and the stability of molding parameters (avoiding appearance defects such as bubbles and shrinkage)

2. Inspection Rules (Strictly Following Clause 7 of the National Standard)

Batch formation: Products continuously produced with the same raw materials and the same production line are regarded as one batch, with each batch ≤1.2 million pieces

Inspection classification:

Factory inspection: Mandatory inspection of appearance (full molding, no impurities, intact tamper-evident band), dimensions, and printing pattern adhesion (no obvious detachment in adhesive tape test)

Type inspection: For scenarios such as raw material/process change, resumption of production after suspension for more than 6 months, and quality problems, all items need to be tested (including physical and mechanical properties and hygiene performance)

Sampling and judgment: According to the double sampling plan of GB/T2828.1, 315/630 pieces are sampled for appearance (AQL=2.5), 100 pieces are sampled for sealing performance (AQL=1.0), and the batch is judged qualified only if all items are qualified; if one item of hygiene performance is unqualified, the entire batch is unqualified

3. Marking, Packaging and Storage (Requirements of Clause 9 of the National Standard)

Marking: The packaging box shall be marked with product name (2925 specification), quantity, trademark, manufacturer information, and storage and transportation graphic marks (complying with GB/T191)

Packaging: Packed in food-grade packaging bags and then boxed in a clean and dust-free environment to avoid pollution

Transportation and storage: The transportation tool shall be clean and dry, avoiding sunlight and rain; stored in a clean and ventilated warehouse at 18℃-38℃, and preheated for 24h before use if the temperature is lower than 18℃; kept away from heat sources and toxic and harmful substances, with a storage period ≤12 months

V. Market Status and Development Trends

1. Current Market Application Status

Has become a benchmark choice for lightweight packaging in the bottled water industry, covering a wide range of needs from first-tier brands to regional brands

Adapted to high-speed production lines (thousands of pieces per minute), meeting the needs of large-scale industrial production

2. Technical Innovation Directions (Complying with National Standard Compliance and Market Needs)

Environmental protection upgrade: R&D of bio-based HDPE and degradable materials to further reduce plastic pollution

Function optimization: Tethered design to prevent cap loss; integration of anti-counterfeiting and traceability functions such as QR codes and laser coding

Performance improvement: Optimize the sealing structure to adapt to more severe storage and transportation environments; refine torque design to improve opening convenience for different groups of people

VI. Summary

With "lightweight, low cost, and high adaptability" as its core advantages, the 2925 bottle cap fully meets the mandatory safety, hygiene, and performance requirements of National Standard GB/T17876-2010, perfectly balancing market value and compliance bottom line. Its structural design focuses on sealing reliability and opening safety, and its application scenarios focus on non-carbonated beverages, especially adapting to modern lightweight PET bottle packaging, and has become the mainstream choice in the industry. In the future, under the background of stricter environmental policies and consumption upgrading, the 2925 bottle cap will continue to iterate towards the direction of "more environmentally friendly, smarter, and more convenient", consolidating its core position in the field of bottled beverage packaging.

Related News

Related Products

undefined