21

2026

-

01

Detailed Introduction to 48mm Smart Cap

I. 48mm Smart Cap Structural Design and Working Principle

1. Structural Composition (In Accordance with National Standard Clauses 3.4 and 5.1)

Component | Function | Design Basis and Characteristics |

Cap Body | Provides structural support and threaded connection | 48mm outer diameter, single-start thread, 4-6 reinforcing ribs on the side, meeting the national standard requirement of "full molding and complete structure" |

Central Pierceable Hole | Insertion channel for the water dispenser's column | Diameter of approximately 25-30mm, built-in 4-6 petal-shaped pierceable tabs with a thickness of 0.3-0.5mm. The thin rib connection ensures easy piercing without falling off |

Pierceable Tab | Dual functions of sealing and easy breaking | Equipped with lever points for concentrated force. After breaking, the petals open outward without affecting water flow, meeting the national standard requirement of "no defects and effective sealing" |

Tamper-Evident Band | Core structure for anti-theft and anti-counterfeiting | Connected to the cap body through 18-20 connecting bridges (National Standard Clause 3.4). The diameter of the connecting bridges is approximately 0.7mm, and the breaking torque meets the national standard requirement of ≤2.2N·m |

Sealing System | Enhances sealing performance | Double structure of inner plug + outer plug, with a sealing ring at the bottom. The compression amount is 0.5-1.0mm, meeting the national standard sealing pressure requirement |

Knurl | Facilitates cap screwing operation | Uniformly distributed on the side of the cap body, meeting the national standard appearance requirement of "smooth surface without burrs" |

2. Working Principle

- Invert the barreled water equipped with the 48mm Smart Cap on the water dispenser's base;

- The weight of the water barrel is transmitted to the central column of the base, exerting vertical pressure on the lever points of the pierceable tab;

- The thin ribs of the pierceable tab break under pressure (approximately 20-35N), and the petals open outward to form a water outlet;

- Water flows into the water dispenser's inner tank through the diversion groove of the base, realizing automatic water supply;

- At the same time, the tamper-evident band is separated from the barrel mouth's clamping groove, and the connecting bridges break, forming irreversible opening traces, which complies with the national standard definition of "being unable to restore the original packaging after opening".

II. Material and Performance Requirements (Strictly Following National Standard Clauses 5.4 and 5.7)

1. Core Materials (In Accordance with National Standard Clauses 1 and 5.7)

Material | Performance Characteristics | Complying National Standards | Application Scenarios |

HDPE (High-Density Polyethylene) | Good toughness, impact resistance, excellent sealing performance, low-temperature resistance (-20℃) | GB9687 "Hygienic Standard for Polyethylene Molded Products for Food Packaging" | Mainstream choice, suitable for various types of barreled water |

PP (Polypropylene) | High-temperature resistance (≤80℃), strong rigidity, excellent chemical stability | GB9688 "Hygienic Standard for Polypropylene Molded Products for Food Packaging" | Barreled water requiring high-temperature disinfection (such as medical purified water) |

Polyolefin Composite Material | Balances toughness and rigidity with comprehensive performance | GB4806.1 "Hygienic Standard for Rubber Products for Food Use", GB9685 "Standard for the Use of Additives in Food Containers" | High-end barreled water pursuing ultimate safety |

2. Key Performance Indicators (In Accordance with National Standard Clauses 5.4, 5.5, and 5.6)

Performance Item | National Standard Requirement | Specific Performance of 48mm Smart Cap |

Sealing Performance | Non-carbonated cap: No air leakage at 200kPa, no cap detachment at 350kPa | No leakage after 48 hours of inversion, pressure test ≥0.2MPa meets requirements |

Temperature Resistance Performance | Non-carbonated cap: No burst or deformation at -20℃~80℃ | Adapts to refrigerated to normal temperature environments without deformation or liquid leakage |

Drop Performance | No cap detachment or liquid leakage | No damage after dropping from 1.4m (small capacity)/1.0m (large capacity) |

Impact Resistance Performance | No detachment of the cap and fragments | No cracking or detachment when impacted by a 286g steel ball from a height of 762mm |

Opening Torque | For specifications of 38mm and above: 0.6N·m~2.9N·m | Controlled at 1.0-2.5N·m, facilitating operation and reliable sealing |

Breaking Torque | Not greater than 2.2N·m | 0.8-1.2N·m, ensuring the connecting bridges break during normal opening |

Anti-theft Performance | If resealed after opening, the connecting bridges show obvious damage | Cannot be restored after breaking, complying with the national standard definition of anti-theft |

Grease Bleeding Performance | No grease precipitation on the liquid surface | No grease bleeding after being placed at 42℃ for 48 hours, meeting national standard hygiene requirements |

Safe Opening Performance | No cap detachment or popping during opening | No popping risk when opening counterclockwise, complying with national standard safety requirements |

Hygiene Performance | Complies with standards such as GB4806.1 and GB9685 | No peculiar smell, no precipitation of toxic and harmful substances, passing GB/T5009.60 test |

III. Application Fields

- Household Water Dispensers: Adapted for 3-5 gallon barreled water, providing a convenient and hygienic drinking water solution that meets household needs for safe sealing;

- Office and Public Areas: Commercial water dispenser systems in office buildings, schools, hospitals, shopping malls, and other places, adapting to high-frequency use scenarios. Anti-theft and anti-counterfeiting features enable traceability;

- Barreled Water Production Enterprises: As a standardized sealing accessory for branded barreled water, it meets national standard quality requirements and improves product compliance and consumer trust;

- Special Fields: Scenarios with high requirements for water quality cleanliness such as laboratories and pharmaceutical factories. The disposable design avoids cross-contamination and complies with hygiene standards.

IV. Production Process and Inspection Rules of 48mm Smart Cap (In Accordance with National Standard Clauses 6 and 7)

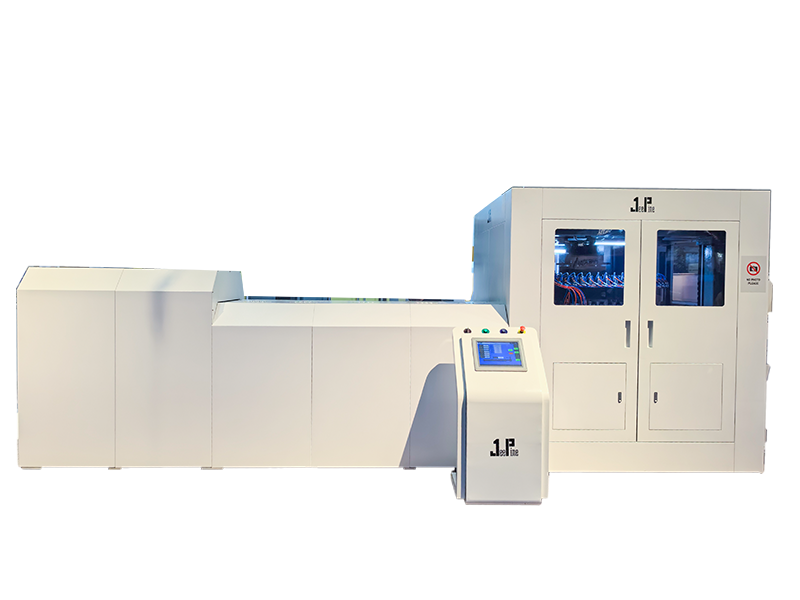

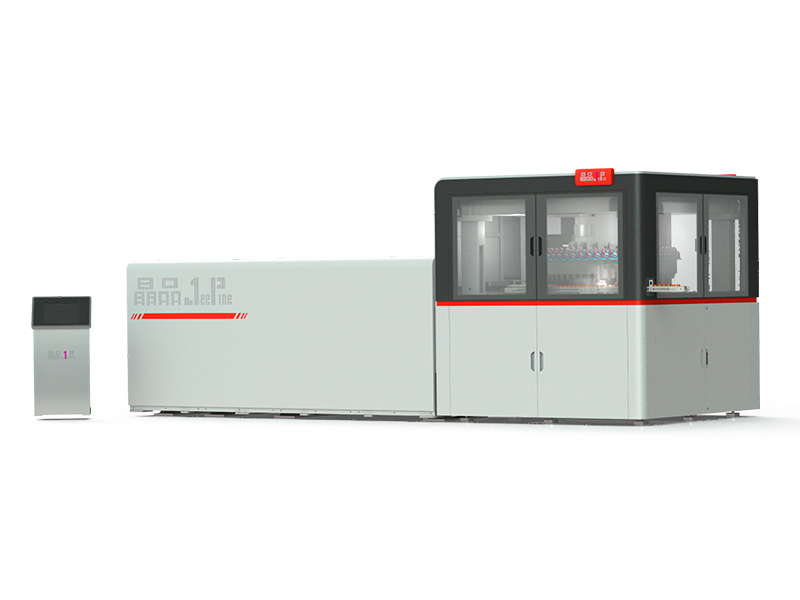

1. Production Process of 48mm Smart Cap

The 48mm Smart Cap mainly adopts the compression molding process, complying with the national standard requirement of "injection molding, hot pressing, or other processes". The production process is as follows:

- Raw Material Pretreatment: Food-grade HDPE/PP particles are uniformly mixed with color masterbatch, meeting national standard hygiene requirements;

- Quantitative Extrusion: Raw materials are extruded into the compression mold according to the set dosage;

- Mold Clamping and Compression Molding: The mold clamps and compresses the raw materials into shape to ensure the 48mm Smart Cap has a full appearance and no defects;

- Ring Cutting Processing: Special equipment processes the connecting bridges between the tamper-evident band and the cap body to control the breaking torque;

- Cooling and Setting: A closed-loop water cooling system rapidly cools the cap to ensure dimensional accuracy meets tolerance requirements;

- Quality Inspection: 360° full inspection with 7 cameras to eliminate products with unqualified appearance and dimensions;

- Packaging and Warehousing: Sealed packaging with food-grade packaging bags to avoid contamination.

2. Inspection Rules of 48mm Smart Cap (In Accordance with National Standard Clause 7)

- Batch Formation: Products continuously produced with the same raw materials and the same production line constitute a batch. Each batch of 48mm Smart Caps shall not exceed 1.2 million pieces;

- Inspection Classification:

- Factory Inspection: Mandatory items include appearance (5.1), dimensions (5.2), and printing pattern adhesion performance (5.3);

- Type Inspection: Full-item inspection (all requirements in Chapter 5). Trigger conditions include new product finalization, material/process changes, resumption of production after more than 6 months of shutdown, quality problem feedback, and requirements from users or regulatory authorities;

- Factory Inspection: Mandatory items include appearance (5.1), dimensions (5.2), and printing pattern adhesion performance (5.3);

- Sampling and Judgment: According to the double sampling plan in GB/T2828.1, the Acceptable Quality Level (AQL) for appearance, dimensions, sealing performance, and other items of the 48mm Smart Cap shall be implemented in accordance with Table 6 of the national standard. If any item of hygiene performance is unqualified, the entire batch of products shall be judged as unqualified.

V. Marking, Packaging, Transportation, and Storage (In Accordance with National Standard Clause 9)

1. Marking

The packaging box of the 48mm Smart Cap shall comply with GB/T191 "Packaging - Pictorial Marking for Handling of Goods", and shall be marked with product name, specification (48mm), quantity, trademark, full name and address of the manufacturer, external dimensions, transportation and storage precautions, and accompanied by a qualification mark.

2. Packaging

Packaging shall be carried out in a clean and dust-free environment. The 48mm Smart Cap shall first be sealed with bags meeting food hygiene requirements, then packed into boxes; the packaging method can also be negotiated by the supply and demand parties.

3. Transportation

Transportation tools shall be clean and dry. The stacking weight of boxed products shall not exceed the bearing capacity of the outer packaging. Avoid exposure to sunlight, rain, pollution, and severe impact.

4. Storage

- The 48mm Smart Cap shall be stored in a clean, dry, and well-ventilated warehouse with an ambient temperature of 18℃~38℃;

- If the temperature is below 18℃, it shall be placed in an environment above 18℃ for 24 hours before use;

- Keep away from heat sources and pollution sources. It is strictly prohibited to mix with toxic, harmful, and strong-smelling items;

- Storage Period: No more than 12 months from the date of production.

VI. Purchase and Use Precautions

1. Purchase Points

- Check Compliance: Confirm that the product complies with the GB/T17876-2010 standard and provide a hygienic performance test report (GB/T5009.60);

- Inspect Appearance: Full molding, smooth surface, no shrinkage, bubbles, burrs, or black spots, and the connecting bridges of the tamper-evident band are intact without breaking;

- Verify Dimensions: Confirm the caliber is 48mm, and the inner plug and thread are compatible with the barrel mouth of your own;

- Pay Attention to Material: Prefer HDPE or PP materials. The packaging shall be marked with "food-grade" and "BPA-free";

- Check Sealing: The pierceable tab is intact without damage, the inner plug is not deformed, and there is no leakage when inverted.

2. Usage Suggestions

- Handle with care during installation to avoid damaging the 48mm Smart Cap or tamper-evident band due to violent operation, which may affect sealing performance;

- The column of the water dispenser's base shall be clean and dry to prevent contamination of the water source;

- Drink as soon as possible after opening, preferably within 7 days to ensure water freshness;

- Avoid direct sunlight and high-temperature environments when storing barreled water to prevent plastic aging from affecting hygiene performance.

As a standardized accessory complying with the GB/T17876-2010 national standard, the 48mm Smart Cap has become the mainstream choice for large-diameter barreled water with its core advantages of reliable sealing, anti-theft and anti-counterfeiting, convenient operation, and hygiene and safety. Its entire process of production, inspection, transportation, and storage follows national standard requirements, providing a solid guarantee for drinking water safety and adapting to the drinking water needs of various household and commercial scenarios.

Related News