05

2025

-

03

Jeepine Cap Compression Machine Usage and Production Process

1. Industry situation:

With the advancement of science and technology, the demand for beverages and other drinks in People's Daily consumption is increasing day by day. However, at present, most beverages are still in bottled form. With the continuous improvement and development of China's market economy and the significant enhancement of people's living standards, the demand for bottle caps is also increasing. The status and role of the packaging industry in the national economy are constantly rising. According to the different levels of economic development in various countries, the more economically developed a country is, the higher the proportion of the packaging industry it accounts for. Therefore, with the continuous development of the global economy and the constant improvement of people's living standards, the demand for packaging industry, especially for bottle cap manufacturing equipment, will become increasingly strong. When it comes to cap compression molding machines, the Italian company Sacmi is generally familiar to industry insiders. As a global leader in the industry, it has been leading the development trend of the industry for decades. In the domestic field of cap compression molding machines, Guangzhou Jeepine has firmly held the leading position, with nearly 130+ patented technologies. Next, let's take a deep dive into the operation process and usage precautions of the Jeepine cap compression molding machine!

2.Operation process:

Cap compression molding machine (CCM), it is a machine to make the cap through the compression molding technology. The main operation process is as follows:

Debugging, debugging the machine, installing the mold

Switch on, start the machine

Feeding, prepare the materials(HDPE) to be used for making bottle caps

Production, to carry out the production of the machine

Testing, testing the quality of the caps

3. Cautions:

Just now we talked about the operation process of the CCM, so what operations of the CCM need to be worthy of attention? The following is a brief introduction to some of the precautions for the use of the Jeepine CCM

3.1 Installation requirements

Ensure that there is enough space for movement where the CCM is installed:

Space to operate the machine;

Space for handling the installation place of the CCM;

Space to be able to dismantle and mount machine parts when carrying out maintenance;

Space to be able to add auxiliary devices when carrying out modifications.

3.2 Transport:

The CCM must be transported by specialised personnel!

When transporting the CCM, special care must be taken to ensure that the correct facilities are used (e.g. crane, forklift, rollers, belts, etc.).

The packing box is heavy and must be handled carefully and gently, never under heavy pressure.

The box must not be tilted, let alone inverted.

When lifting, take the bottom of the packing box as the lifting point, and the whole machine should not be tilted more than 10°.

It is recommended that you choose the appropriate crane according to the weight of the equipment and the packing box (the weight of the machine is about 12000KG, the crane should be 15 metric tonnes or more).

3.3 Storage:

Temporary storage:

If, for various reasons, the capping machine has to be stored in the warehouse for a period of time before it is put into use, then:

Before storage, please open the packing box to make sure that the equipment has not been damaged during transport and handling.

The temperature in the storage room of the equipment must be kept within the range of -10°C to +50°C allowed for the equipment.

Please ensure that the environment in the storage room is dry, clean and ventilated.

Prohibit stacking other items on the equipment.

Take relevant precautions to prevent the equipment or parts from being damaged due to humidity or other reasons.

3.4 Long-term storage:

The machine must be completely cleaned out;

The equipment storage room must have good temperature and environmental conditions;

It is forbidden to stack other items on the equipment.

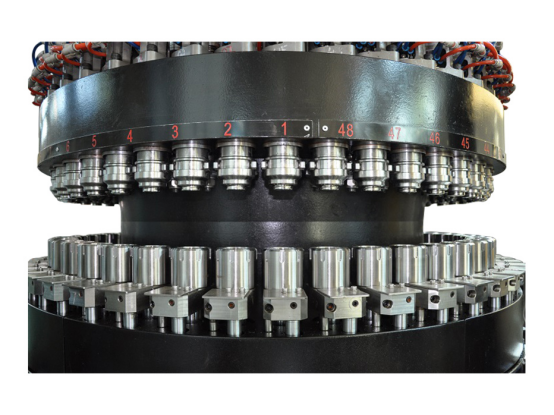

4. Product specification

After knowing the operation process and precautions of the capping machine, what are the corresponding product specification?

Capping method: compression molding

Maximum output (3025 caps):

(24 cavities) 36,000 - 40,000 pcs/hour

(48 cavities) 80,000 - 85,000 pcs/hour

(54 cavities) 95,000 - 100,000 pcs/hour

Number of cap-making cavities: 24--48 cavities

Power supply voltage: AC380V/50Hz-3P+N+E

Auxiliary voltage: 24V

Total power (installed capacity): 90Kw (different model will have different power)

Equipment size: depending on different models

Equipment weight: 7T (depending on different models)

5.Features and Advantages

This cap-making machine is a fully automated cap compression molding machine independently developed by us. It integrates the advantages of similar products from internationally renowned companies and is closely combined with China's specific national conditions. This equipment is suitable for the production of mineral water bottle caps, carbonated beverage bottle caps, high-temperature resistant juice bottle caps, cosmetic bottle caps, medical supply bottle caps, edible oil bottle caps and other types of plastic bottle caps. It adopts a large number of innovative technologies, advanced processes and brand-new structures, and its product quality ranks among the leading levels in the industry. The bottle caps produced by this equipment have no injection molding marks, are of excellent quality and exquisite appearance, and their overall performance reaches the top level in the same industry. In addition, the equipment is easy to operate, energy-saving and environmentally friendly, and can significantly save electricity, water resources, raw materials and labor costs. At the same time, it significantly reduces the consumption of cooling water and eliminates the generation of gate waste. It features high production efficiency, adopts a continuous assembly line operation mode, and it is convenient to change materials and molds. The transmission is precise and stable, the process design is scientific and reasonable, the whole machine structure is compact, the floor space is small, and the return on investment is extremely high.

6. Summary

Guangzhou Jeepine Intelligent Compression Molding Machine Co.,Ltd focuses on the research and development of high-efficiency and energy-saving compression molding equipment technology. The high-efficiency and energy-saving cap compression molding machine independently researched and developed by the company has been selected as one of the first sets of national major technological equipment promotion catalogue, which reaches the domestic leading level, breaks the monopoly of foreign countries, and enters into the use of Wahaha, Yinlu ,Wuliangye, Mengniu, Jianlibao, Chi Forest, Runtian and Taiji Group, and is exported to Africa, Southeast Asia, the Middle East, India, South Korea, and the United States, and is widely used in drinking water, wine, foodstuff and other beverage industries. It is widely used in drinking water, beverage, alcohol, medicine, daily packaging and other industries, and has broad development prospects and market space.

Related News

Related Products

undefined